How to clean and re-seal stamped concrete

Updated October 30, 2023

Author: Michael Day

Is your stamped concrete looking a little faded, blotchy, or even kind of whitish on the surface and you want to restore it to its original look when the concrete was first sealed?

Let me teach you how to properly clean and re-seal your stamped concrete so it can look BRAND NEW!

Does your sealer look like this? Does your sealer look like this? |

In theory, resealing your stamped concrete should be quite easy, but if you're not careful, resealing it might make it look worse. |

*Very Important:

How could applying new sealer make my concrete look worse?

First of all, sealing a new stamped concrete floor is very different than re-sealing a stamped concrete floor. Re-sealing a stamped concrete floor may be a little more challenging if not done correctly.

Concrete sealers are designed to be applied very thin.

The manufacturer specifies on the label how many square feet per gallon of coverage. If they specify 300 square feet per gallon then that's what you should do. If you think applying it at 200 square feet per gallon is better because it's a little thicker, you're wrong.

Applying the sealer too thick can cause:

- Blisters and Bubbles occur

- White haze look

- Roller marks

- Peels or Flakes off

- Dark / Blotchy spots

They key to successfully re-sealing your stamped concrete is making sure you correctly prep the concrete before-hand. If you already have blushed (whitish) looking sealer that looks like a thick plastic coating, kind of peeling and flaking off, then applying a new coating of sealer over it will eventually trap more moisture and make the concrete look worse.

Have you been asking yourself:

SHOULD I RESEAL MY STAMPED CONCRETE?

|

Well, if your stamped concrete is looking whitish, peeling or flaking off, then the answer to that is YES. If you're like me, you like your stamped concrete looking new, clean, and either shiny or with more of a matte finish. Let me tell you how to achieve this, |

|

There's some things you have to do before re-sealing your stamped concrete driveway, patio or pool deck.

CLEANING STAMPED CONCRETE

Can you use a pressure washer to clean stamped concrete?

Yes, I recommend using a pressure washer but with a certain kind of tip.

|

A 15" rotary surface cleaner like this one you can get on Amazon, will attach right to the end of your pressure washer wand and is the best way to clean your stamped concrete without damaging the concrete. |

|

|

You'll need a good pressure washer, preferably a 3100 - 3300 psi one, to get the best cleaning results if you use the rotary surface cleaner. If you don't have one of that strength, you can rent one or buy one from Amazon like the one here. |

|

You're not trying to remove all the original concrete sealer. You just want to remove the dirt, tree pollen, mold & mildew and debris from the surface.

In the process of doing this, this surface cleaner will also remove any old, loose, and flaking sealer that was originally applied.

If you feel like you still have some dirty areas after using the surface cleaner and you need to scrub the surface, you can use a stiff bristle broom and Dawn dish detergent or Simple Green mixed with water in a 5 gallon bucket.

Either way, Just rinse the concrete really good so no residue remains after it dries out.

IMPORTANT: When you're done cleaning and washing the concrete, it's very important to let it dry out. Wait at least 24 hours, 48 would be better. Even though the concrete looks dry on the surface, there's still a lot of moisture internally.

Cleaning supplies

Now, Let's Start RE-SEALING your STAMPED CONCRETE

WHAT TYPE OF SEALER SHOULD You USE TO ADHERE TO THE OLD SEALER?

Check out this video to find out my 2 favorite sealers to use

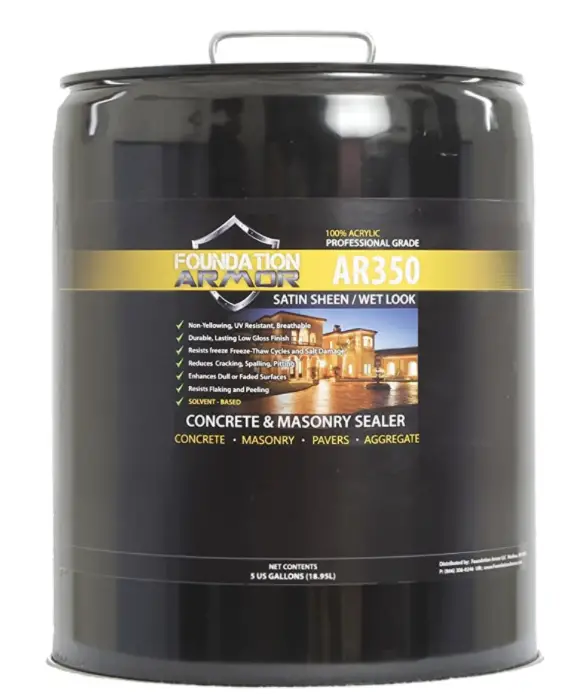

Foundation ARMOR ar350: solvent based acrylic sealer

|

For a Solvent Based Acrylic Sealer, I recommend Foundation Armor's AR350 Solvent Based WET look Acrylic based stamped concrete sealer. This sealer will darken the concrete and enhance the color in the concrete, while leaving you with a nice Satin Sheen (low gloss) on the surface. |

Radonseal lastiseal penetrating sealer: water based

|

For a water based sealer, I recommend using the RadonSeal Lastiseal Penetrating Sealer. This sealer penetrates deep into the concrete, is ECO-friendly, protects against freeze-thaw, prevents spalling, and is waterproof. |

Most stamped concrete contractors like myself use solvent acrylic based sealers on our stamped concrete projects. The solvent sealers make the colors "POP" and generally work the best. Especially for exterior stamped concrete.

If you prefer a HIGH GLOSS shine to your stamped concrete, I would consider using Foundation Armor's AR 500 High Gloss Sealer.

How do I apply the sealer?

|

This is what I use to apply the sealer. It's the Chapin Extreme 3.5 gallon Stainless Steel Sprayer. You need a good sprayer! If you use a cheap one, the solvents in the sealer will destroy the seals and make the sealer useless. This sprayer has special seals that won't get damaged when you use a solvent based sealer. You can also get this on Amazon. |

|

This pump up sprayer also has a very fine tip that gives you a nice evenly sprayed surface. Other sprayers tips just spray out too much sealer and you end up with an uneven look and too much sealer on the surface. We clean out the sprayer after each use with the same solvent that's in the sealer (straight acetone or xylene) and you can re-use it over and over again for years. Just dump in 8 - 10 oz after you empty out any left over sealer, pump it up and spray it out. Repeat one more time and your sprayer, and the tip, is clean. |

Will the surface be slippery after I seal it?

The chances are low with my 2 favorite sealers, however it could be.

If you're worried about your stamped concrete being slippery, you can add Foundation Armor's NON-SLIP ADDITIVE to the sealer when you apply it.

Re-Sealing the concrete - Step by step guide

- Make sure the stamped concrete is COMPLETELY DRY. After you clean the concrete, give it 24 to 48 hours to dry before re-sealing.

- Fill the sprayer about 3/4 full of sealer, tighten the top and pump up the sprayer until it's really hard to pump.

- Begin spraying your sealer in circular motions from one end to the other. Follow the directions carefully that are given to you by the sealer company. The first layer should be very thin.

- Once the first layer completely drys, which usually takes around 20 minutes, you can begin to apply the second and final layer.

How much sealer will I need?

|

Whenever I seal or reseal stamped concrete, I like to go very thin with the first coat. I might spray it on as thin as 500 sq. ft. per gallon. It's so thin, it looks like I'm missing some areas. The goal is to use as little as necessary to get the job done. Less problems that way. If I think I need a second coat I'll wait until the first is completely tack free and spray on another one at 400 sq. ft. per gallon. |

|

THE Best TIME TO RE-SEAL stamped CONCRETE

- When the temperature is between 55 and 80 degrees

- Late in the afternoon or early evening when the sun is going down

- When you have multiple days of dry, sunny weather

WHEN NOT TO RE-SEAL STAMPED CONCRETE

- When the temperature is 80 degrees or hotter

- When the temperature is below 55 degrees

- In direct sunlight in the middle of the day

- Early in the morning when there's dew on the ground

- When it rained the day before (remember, allow a full 24-48 for concrete to dry)

- When there's a chance of rain the day of

- When it might rain the day after

- When it's windy outside

- When the existing sealer just looks like it's too thick (this is when you'll have to strip it off and start over)

How often do you need to re-seal stamped concrete?

You should re-seal you stamped concrete every 2 - 3 years. It depends on things like, foot traffic, sunlight, and weather conditions.

Acrylic sealers just aren't designed to last forever. The sun degrades them, foot traffic wears it off, and harsh weather conditions will eventually make it whiten or flake off.

Maintaining the stamped concrete by keeping it clean and re-sealing when needed (2 - 3) years, will keep the concrete looking as new as possible.

Can Xylene be used on stamped concrete?

|

TIP: To clear up whitened, cracked, and hazy looking concrete sealer, sometimes it's better to try and re-melt the existing acrylic solvent based sealer with an application of xylene (xylol). You can also clean your sealer sprayer with Xylene. |

Xylene is a strong solvent that re-wets acrylic solvent based concrete sealers making them look new again.

Applying xylene by using a pump-up sprayer, roller, or brush rejuvenates the existing old sealer to its original appearance. By trying this method first, you may get the original sealer to look smooth, shiny and clear without adding another coating of sealer, which will save you some money.

What xylene won't do is seal any areas where the old sealer has completely peeled, flaked, or worn off. You might try a xylene application first, wait a few hours for that to dry, then reseal everything with a very light coat of new sealer.

HOW TO TELL IF YOUR DULL STAMPED CONCRETE IS already SEALED

If you view the concrete at an angle and the surface has some sheen, it probably has some sealer on it.

Another way to test for existing sealer is after the concrete has been completely cleaned, place a few drops of water on it. If the concrete immediately darkens, the sealer is gone. If the water beads up, even for a few seconds, there's still some sealer on or in the concrete.

Why is this important to know?

If your stamped concrete is just dull looking with no white spots or flaking, then just a simple cleaning and re-seal should be enough to make it look like new again.

How much does it cost to re-seal your stamped concrete?

If you re-seal the stamped concrete yourself, all you will have to pay for are the supplies.

If you hire someone to come re-seal the stamped concrete, it usually costs $1 per square foot plus the cost of their time and labor.

re-sealing supplies

- Roller

- Paint tray

- Stainless Steel Sprayer

- Foundation Armor AR350

- RadonSeal Lastiseal

- Foundation Armor Non-Slip Additive

IN SUMMaRY

It's a good idea and good maintenance to re-seal your stamped concrete.

Watch my videos above, I break down each step from cleaning to sealing your concrete.

If you have a question, you can watch the video on YouTube and ask a question in the comments section. I try to answer all questions asked on that platform.

You can also check out the CONCRETE UNDERGROUND to learn more about concrete.

Mike Day

Disclaimer: Some of the links on this page are affiliate links. If you click on the link and purchase the product I receive a small commission. Thank You!