What type of concrete sealer should I use?

There's just no simple answer to that question without knowing what your situation is.

By reading the information I have written for you below, my hope is you can find the answer to that question.

That's me spraying a solvent based acrylic concrete sealer on some stamped concrete

That's me spraying a solvent based acrylic concrete sealer on some stamped concreteApplying a concrete sealer to new or old concrete is definitely a good idea.

Curing and sealing the concrete will help protect it and enhance the concrete's appearance for many years to come.

But, knowing which type of sealer to choose for your specific application can be a little challenging.

I wrote this page to help you understand the differences between the different kinds of concrete sealers. Specifically, what they do and when and where to use them.

For example:

Maybe you just acid stained your concrete floor and you want a durable, scratch resistant sealer that will enhance the color of the stain.

Or you have a stamped concrete patio and want to know what's the best sealer to protect it from freeze / thaw climates.

This guide will help educate you about the different types of concrete sealers and how to pick the right one.

This is what a properly applied concrete sealer will do to protect your concrete.

This is what a properly applied concrete sealer will do to protect your concrete.There's basically 2 types of sealers for concrete surfaces:

PENETRATING SEALERS and FILM-FORMING SEALERS.

Penetrating Sealers are made with silane & siloxane, they penetrate deeply into the pores of the concrete and form a chemical bond within the capillaries of the concrete to protect against moisture penetration and deicing chemicals.

They provide invisible protection

and don't usually change the surface appearance.

When you apply this type of concrete sealer, it actually soaks down into the concrete, expands and fills the pores in the concrete.

It'll help improve the durability of exterior concrete surfaces exposed to harsh weather conditions like freeze-thaw damage.

This is a good sealer to choose if you want a natural matte finish.

For some penetrating sealers, the concrete must be fully cured (at least 28 days old) before you seal the concrete with it.

There are some brands that can be applied to concrete less than 28 days old. It's always a good idea to check the product data sheet before using the sealer.

What would I use a penetrating concrete sealer for?

- If you want the concrete to look natural "as is" and NOT glossy or shiny.

- This kind of sealer will NOT make your concrete any more slippery than it would be without a sealer.

- If you don't want to change the look or color of the concrete, use this kind of sealer

- To repel water and reduce water absorption into the concrete by up to 95%

- To make your concrete more resistant to snow and ice, road salts, mold and mildew, and staining.

- I use this type of sealer for pool decks, sidewalks, concrete driveways, stamped concrete, concrete patios, and garage floors.

What I recommend using for a penetrating concrete sealer

I recommend using RadonSeal's deep penetrating concrete sealer.

You can use it on your garage floor, your basement floor, it's great for protecting exterior concrete like driveways, pooldecks, and sidewalks.

It's what I use for my business when I seal my customer's concrete projects.

Don't forget to get a good pump up sprayer like I'm using in the picture above.

DENSIFIERS & HARDENERS - are another form of penetrating sealer.

This type of sealer is made with a unique blend of siliconate and silicate polymers specially formulated to penetrate deep into the concrete surface and chemically react to produce a very dense and durable surface.

This type of sealer actually helps strengthen the surface.

You can use this type of sealer on concrete floors that seem soft or dusty on the surface. It'll harden the surface and help fix this problem.

This kind of sealer is also used when you're going to polish concrete floors and slabs.

A. Dustproofs concrete surfaces

B. Use on new or existing concrete floors

C. Reduces tire marking

This sealer can be applied to concrete that's 1 day old or older. You don't have to wait until it's fully cured.

What I recommend for a Densifier/Hardener silicate concrete sealer.

This is a good silicate densifier & hardener sealer you can get on Amazon.What's the difference between silane/siloxane vs silicate/siliconate penetrating sealers

The main difference is:

Silane/Siloxane sealers are classified as "water repellent sealers". Their primary function is to make concrete more resistant to water absorption and the damaging effects water can have on concrete.

Things like cracking, scaling, surface delamination from freeze/thaw cycles. This sealer does not increase the strength of the concrete.

Silicate/Siliconate sealers are classified as "densifiers". They strengthen the concrete by reducing the size of the pores in the concrete. This makes the concrete more resistant to deterioration from surface abrasion.

This sealer will not stop or reduce surface water absorption.

You have to decide if you want a sealer that blocks water or one that strengthens the concrete.

Film-Forming or Topical sealers do just what the name says, form a protective film on the surface of the concrete. They are most often used on decorative concrete work and interior concrete floors.

Most of them also enhance the colors in stamped concrete or concrete acid stained floors.

With a film-forming sealer you have three types,

each having advantages and limitations.

1. ACRYLIC BASED SEALER - comes in both water based and solvent based versions. They are usually the easiest to apply and the most economical.

This type of sealer leaves a visible "film" behind or a thin coating on the surface of the concrete after you apply it.

It could be slipperier than a penetrating concrete, especially when wet, because of the coating on the surface.

They are UV resistant, non yellowing and provide good protection against water and deicing chemical absorption. They are usually applied somewhat thinner than polyurethanes or epoxies, wearing out faster and requiring resealing more often.

- Can be used on both interior and exterior concrete

- Enhance the beauty of colored, stained, stamped or exposed aggregate concrete

- Fast drying will usually dry to the touch within an hour

- Come in different sheen levels, low or high gloss, solvent based usually enhance color better than water based

What would I use an acrylic based concrete sealer for?

- To protect the surface of the concrete from staining and deterioration

- To enhance the color of the concrete, especially stamped concrete

- To enhance dull or faded, decorative concrete surfaces

- If you want a gloss or have a "wet look" to your concrete

- If you want a sealer that's easy to apply, just make sure to follow the manufactures instructions

- If you want a solid colored surface - this type of sealer comes in all kinds of different colors as well as clear

- Can be applied over a previously applied acrylic based sealer to re-seal the concrete if needed. Water based over water based and solvent based over solvent based. NOT water based over solvent based.

- I use this type of sealer for basement floors, garage floors, stamped concrete, on stained concrete floors, and exposed aggregate concrete.

If you're using this for an interior floor with little to no ventilation, you may want to choose the water based version.

2. URETHANE SEALERS - Are stronger, more durable, more scratch & chemical resistant, and longer lasting than acrylic sealers.

They are also more expensive and require more surface preparation than acrylics. But they do protect the concrete better.

A properly applied urethane sealer forms a thin (3 - 5 mils) coating on the surface that blocks water and other liquids like oil and gas spills from absorbing into the concrete.

They're not as easy to apply as an acrylic but by thoroughly reading the manufactures instructions can be applied by a diy'er.

Urethane sealers are only used on interior concrete floors.

These are also available in water and solvent based formulas.

They come in clear and also up to 15 different colors.

These sealers don't like moisture until they fully cure, if any water is present on the surface of the concrete when the sealer is applied you will probably get some bubbling or foaming.

You can use this sealer for:

- Garage floors

- Kennel floors

- Warehouse floors

- Airplane hangers

- Retail & showroom floors

- Automotive shop floors

- On stained concrete floors

Some of the benefits of using a URETHANE SEALER VS AN ACRYLIC SEALER ARE:

- Much more resistant to oil, gas, urine, blood, harsh liquids and chemical spills

- Will last longer, much more wear resistant

- Gives you a more UV stable high gloss finish

- Better protection for high foot traffic or vehicle traffic areas

- Better for stopping concrete dusting

Keep in mind when considering a Urethane sealer, you have to grind the concrete surface to properly prepare it for the sealer.

Urethane sealers will NOT form a good bond to smooth concrete and will eventually start peeling off.

For most of you, this means renting a concrete grinder and grinding the surface of your floor to a 25 - 80 grit finish.

This is very doable but just requires you to invest more time and work in the prep for a better end result.

3. EPOXY SEALERS - Like a Urethane, epoxy sealer is more durable, stronger, longer lasting and offers more protection than acrylic sealers.

Epoxy will adhere better to a properly prepared concrete surface than a urethane or an acrylic sealer will.

Also like a Urethane, epoxy comes in 2-parts, a resin and a hardener, that are mixed together with either a 1:1 or 2:1 ratio of resin to hardener.

Epoxy sealer requires more of a learning curve to apply than an acrylic sealer. It has to be mixed properly, the concrete surface needs to be prepared properly, and the epoxy applied properly for a successful end result.

A good 2-part epoxy sealer goes on a little thicker (3-12 mils thick) than a urethane (3-5 mils) or an acrylic (1-3 mils).

Since they go on thicker, epoxies will give you a very hard, long lasting, durable finish that offers you more protection than the other sealers do.

Only use epoxy on interior floors & projects. Not to be used on exterior concrete.

Epoxy sealer completely seals the surface of the concrete. Water, oil, gas, and other liquids will not penetrate into the concrete.

You can use this sealer for:

- Garage floors

- Basement floors

- Shop floors

- Retail stores

- Commercial office floors

- Auto shops

- Airplane hangers

- Decorative concrete floors

- Dog kennels

Why would I use an epoxy sealer instead of a urethane sealer?

- Epoxies are applied thicker offering you more protection to the concrete.

- In my opinion, epoxy is easier to apply.

- Epoxy sealer will penetrate deeper into the surface and adhere better to properly prepared concrete.

- Because they go on thicker, epoxies will hide smaller imperfections in the surface better than urethanes.

What's the best choice of concrete sealer for protecting my concrete?

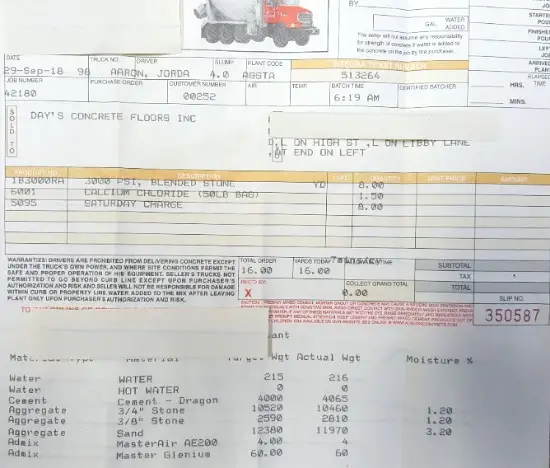

I install a lot of these concrete sealers and have for years. My company, Day's Concrete Floors, Inc. specializes in pouring, finishing, and sealing concrete floors.

In my opinion, a combination of epoxy as a base coating and a urethane top-coat will offer you the best protection for your concrete.

The epoxy for better adhesion and a thicker build, then the urethane which tends to be even harder and more chemical resistant than epoxy.

The trouble is, you really need some training to install an epoxy coating and a urethane top coat. It's not really a diy kind of sealer.

We don't apply epoxy coatings to exterior concrete either. The UV rays from the sun tend to yellow the epoxy.

If you're a homeowner and want to seal your own concrete, I'd stick to using a penetrating or a topical acrylic concrete sealer.

I'd recommend hiring a professional to install epoxy and polyaspartic coatings.

Polyaspartics & Polyureas

This type of concrete sealer is really not a "diy" type of coating in my opinion.

This is an excellent type of sealer/coating for concrete but does take some training to be able to install it correctly.

It typically dries very fast and you don't have very much time to roll it on.

I use this type of coating when I install my 1-day flake floors for garages.

Most of the time there is 3 of us, very experienced installers, when using this product and installing these floors.

What makes Polyaspartic / Polyurea coatings so great:

- Have a very rapid cure time - 1 Hr in most cases

- Cures in very low temperatures - unlike epoxy and urethane

- Has a higher abrasion resistance than epoxy and urethane

- UV stable, will never turn yellow - some epoxies will

- Can withstand higher temperatures and thermal shock than epoxy and urethane

- Adhere excellent to properly prepared concrete

- Dries crystal clear with a high gloss look

- Excellent chemical and stain resistance

- Comes in a variety of colors as well as clear

Before pic of polyaspartic 1 day flake floor

Before pic of polyaspartic 1 day flake floor After pic of polyaspartic 1 day flake floor

After pic of polyaspartic 1 day flake floorPolyaspartic / Polyurea coatings are very expensive. Most are over $100.00 US per gallon. Another reason you might want some training before using this product.

Here's a polyaspartic concrete sealer you can check out on Amazon.

There are other sealers called concrete cure and seal these are a hybrid formula that

both cure and seal concrete in one application.

They're designed to be used more for curing new concrete than for sealing and protecting concrete.

They come in water and solvent based acrylic

resins. Click the link to learn more about this type of sealer.

COMMON QUESTIONS ABOUT CONCRETE SEALERS:

What's the best concrete sealer to use on my concrete driveway?

How do I reseal stamped concrete?

Learn how to remove old, white concrete sealer.

My choice for the best concrete sealer for a pool deck.

What is the best place to use an epoxy sealer?

What are the Pros and Cons of epoxy and urethane sealers?

Can I use a tinted sealer on my floor to add some color?

What kind of sealer surface preparation is required for proper adhesion to the concrete?

Can I use chemical strippers to remove old sealers from the concrete?

Will concrete sealer and condensation cause a sealer look hazy or white?

What are these sealer blisters and bubbles that have formed on the surface?

Can concrete moisture problems cause a sealer to turn white or peel off?

Are deicing salts and concrete not a good mix?

What are the Pros and Cons of concrete penetrating sealers?

What are the best Sealers for driveways