My "Favorite" Epoxy Concrete Crack Repair Product

What's my favorite crack repair epoxy?

It's called CrackWeld and it's from radonseal

Crackweld is a concrete crack injection repair product that you can use to repair cracks in concrete floors, slabs, and driveways.

It can also be used to repair concrete spalling, holes in concrete, and pitted concrete floors.

It's actually a 2-part polymer resin (see below) that's much easier to use than the 2-part epoxy repair products.

The reason it's my favorite is because of how much more user friendly it is compared to all the other repair products I have used. (I list more reasons I like it better below)

CrackWeld has a much lower viscosity than most epoxy crack fillers. The very low viscosity allows you to repair cracks from hairline width up to 1/2" wide.

Who Am I? I'm a concrete crack repair contractor

Hi, and thanks for visiting my page about epoxy concrete crack repair.

My name is Mike Day, I own Day's Concrete Floors, Inc. My company specializes in repairing cracks in concrete floors and walls.

After using many different kinds of repair epoxies, I've finally found the secret weapon when it comes to fixing cracks in concrete.

Through a lot of trial and error, this concrete repair product has outperformed and was easier to use than all the other ones I have tried in the past.

Why I like it so much better than others repair epoxies

This is the same kit I use to repair cracks in concrete floors and slabs. Sometimes mistaken for epoxy it's actually a 2-component rigid polyurethane polymer.

The advantages of using this type of material to repair cracks are :

- NO NEED TO "ROUTE OUT" THE CRACK – Eliminates the process of grinding out or chiseling the crack

- REPAIRS HAIRLINE CRACKS EASY – Repair mixture is very liquid, seeps right into small cracks

- DRIES QUICKLY – Gets hard in 15 minutes so you can epoxy over it, drive over it, or just plain use the floor again.

- HIGHER STRENGTH THAN CONCRETE - It actually "welds" the concrete back together like it was never cracked in the first place.

- CAN USE IT IN COLD WEATHER - The repair formula will harden even in below zero temperatures. (another reason I love this stuff over other products)

RadonSeal has a PRO kit for contractors and a DIY kit for homeowners

I personally use the PRO kit because we repair a lot of cracked concrete floors and the duel cartridges repair more lineal feet of cracks without having to stop as often.

If you only have a small (less than 50 lineal feet) amount of cracks to fix, then I would suggest you use their diy crack repair injection kit.

If you have more than 50 lineal feet of crack repair, you may want to compare the costs between the PRO kit and the DIY kit.

How many lineal feet will each kit repair?

CrackWeld DIY concrete floor repair kit:

- 2-pack kit: Up to 50' of 1/16" crack or 25' of 1/8" crack

- 4-pack kit: Up to 100' of 1/16" crack or 50' of 1/8" crack

NOTE: You use your own single cartridge caulking gun with the diy kit.

CrackWeld PRO concrete floor repair kit:

- 2-duel cartridges kit: Up to 100' of 1/16" crack or 50' of 1/8" crack

NOTE: The PRO kit comes with a duel cartridge caulking gun.

If you already have a duel cartridge caulking gun like the one in the picture above, then you can buy the PRO consumables repair kit and save some money.

YES, I want the diy concrete crack repair kit!

No, I actually need a foundation crack repair injection product.

Same picture as above after repairing the crack with CrackWeld

Same picture as above after repairing the crack with CrackWeldCan I use CrackWeld to repair cracks in a concrete driveway?

The simple answer is YES, as long as the crack is "dormant" (not moving) it will work excellent for this.

If the crack is "active" (still moving) either with expansion/contraction or you live in a freeze/thaw climate, then you would be better off using RadonSeal's flexible Elastipoxy concrete repair kit.

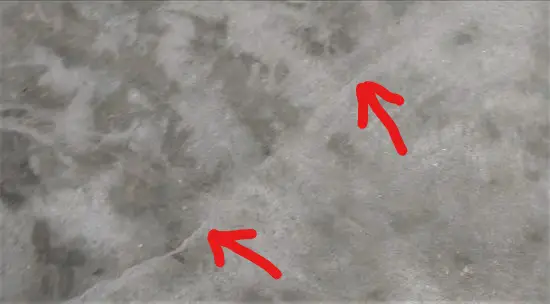

Can I use CrackWeld for other types of concrete repairs?

YES, this is another one of my "secrets" about this product, let's keep this just between us, ok.

It works great for repairing:

- Spalling or pitted concrete that mostly occurs from salt dripping off cars and trucks in places that get snow and ice.

- Small to medium size holes in concrete (I mix it with dry sand and make a paste to do this).

- Fixing chipped or spalling concrete stairs (make a past out of it if you need to).

- Repair damaged saw cuts (expansion/contraction joints)

That's what I like about this product so much, it's very versatile. If you mix it with some silica sand and make a paste, you can use it to fix a lot concrete problems.

Is this really a "do it yourself" concrete crack repair product?

It is, I promise you. This is the most user friendly concrete floor and slab crack repair kit I have ever used.

I've been repairing cracks in both concrete floors and foundation walls for many years, too many to actually tell you, it will embarrass me.

Seriously though, this is the stuff you want to get to fix a crack. Don't waste you time or money on other epoxy repair products.

I use CrackWeld in my business to repair cracks in floors for all my customers. I wouldn't use it or recommend it if I truly didn't feel it was the best crack repair product out there.

All you need to do is follow my tutorial below and watch my video of us repairing a crack in a garage floor.

After you do both of those things, I am confident you'll be more than capable of fixing your own cracks, whether it's a basement floor crack, a garage floor crack or any kind of floor crack.

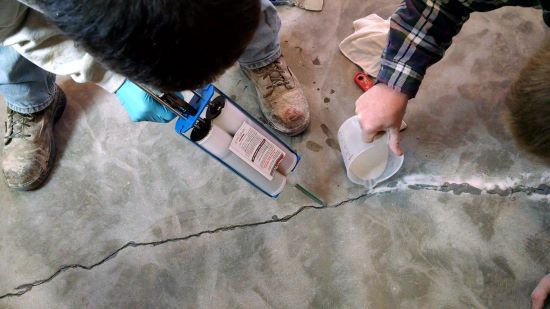

How do you repair a floor crack using CrackWeld

Here's the simple FORMULA for fixing a crack.

I also have a tutorial video below so you can watch me fix a garage floor crack.

- Clean out the crack with a vacuum, remove any loose cement or aggregates.

- Inject the concrete crack repair resin into the crack to wet it, it will soon get tacky.

- Push the dry silica sand into the crack to fill it.

- Thoroughly saturate the sand with the concrete floor crack repair resin and fill it to the surface.

- In 10 - 15 minutes scrape the surface level with a putty knife.

- Sand the surface smooth or lightly grind it with a hand grinder for a neat appearance.

TIP: If the cracks are very small, narrow or jagged, you may have to rout them out with a diamond blade and 4" hand grinder. Making the crack a little wider with smoother edges will make for a better and stronger repair.

If you've never used a 4" grinder with a diamond blade, find someone who has and let them do it for you. You could also try a file or screwdriver to help widen the crack.

Use the moist material you just scraped off with the putty knife to patch any holes, chips or scaled areas in the concrete floor.

Hairline cracks can be done without the sand. Wide cracks can first be filled partially with the sand then start with step 2.

This crack repair material sets up very quickly, only do 10 - 15 feet at one time.

RadonSeal makes a Do It Yourself epoxy concrete crack repair Kit that has all the repair materials included. They also have a great video that visually explain how to use this epoxy crack patching material.

Watch and I'll teach you how to use the CrackWeld concrete floor repair kit:

I want the diy concrete crack repair kit.

I want the PRO concrete crack repair kit like in the picture above.

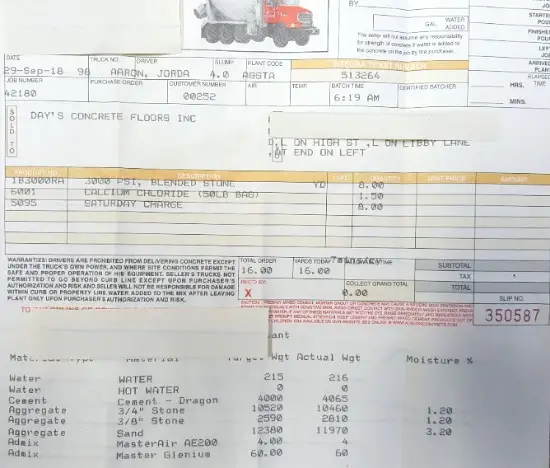

What might be the reason my floor cracked?

It's hard to say without actually looking at you concrete floor. If I look at it I can usually tell pretty quickly.

Here are the most common reasons why concrete floors crack:

- The sub-base wasn't properly compacted and the concrete settled in one area causing the floor to sink and crack.

- The concrete floor isn't heated in the winter and the dirt under the concrete freezes causing it to expand and lift or heave, the concrete. This upward pressure will make the concrete crack.

- Newly poured concrete shrinks when it dries. If no expansion joints are cut into the concrete floor then shrinkage cracks will appear at some point in the future. These are quite common.

Here are some other reasons why concrete cracks:

- Pouring the concrete too wet

- Or too much calcium chloride was added to the mix and it dried too fast

- Or the concrete wasn't properly cured and sealed.

All these reasons could eventually lead to shrinkage cracking at some point.

If you determine the concrete floor cracks are due to settling or heaving, then that's a sub-base issue and the concrete may have to be removed to correct the problem.

Repairing these cracks will only be temporary if the concrete continues to move up or down.

If you're sure the concrete floor is done moving, you can repair those cracks and any shrinkage cracks with CrackWeld, just add a silica sand for a filler. (like we do in the video)

This repair mortar will weld the crack back together creating an excellent concrete floor repair.

In Conclusion:

I don't know what else I can say. CrackWeld is a great product, the people over at RadonSeal, Joe, Craig, and the rest of the gang are top notch.

For me to be successful in my business, I need to work with people I can count on, and use products that won't let me down.

I highly recommend using this to fix your cracked concrete floor!

If you've read this far, I have a special offer just for you

In case you couldn't tell, I install a lot of concrete floors and slabs for a living.

It's what we do the most of here at Day's Concrete Floors, Inc.

I have a CONCRETE SLAB COURSE that I made to teach people how to install their own concrete slab.

The course is designed to help people save a ton of money by being able to build the forms and pour the concrete slab yourself.

For more interesting information about concrete stuff:

This crack repair kit is my "secret weapon" I use to fix cracks in basement walls and stop them from leaking.

Click on CONCRETE JOINT SEALANT to learn how to install sealant in expansion and contraction joints to keep them from failing.

Learn How I repair badly damaged concrete walks, driveways, and patios.

Click on REMOVING CARPET GLUE FROM CONCRETE to learn how to do that.

HOW TO RESURFACE A CONCRETE DRIVEWAY

HOW TO REPAIR CONCRETE DRIVEWAY CRACKS

HOW TO RESURFACE A CONCRETE POOL DECK

WHAT IS CONCRETE EFFLORESCENCE AND HOW TO REMOVE IT.

FOUNDATION CRACK REPAIR - HOW I DO IT

CONCRETE FLOOR CRACK REPAIR - HOW I REPAIR CRACKS

HOW TO REPAIR SPALLING CONCRETE