what is a CONCRETE EXPANSION JOINT?

A concrete expansion joint is a material placed in the concrete slab during the construction process to allow for expansion and contraction of the concrete due to changes in temperature and moisture levels.

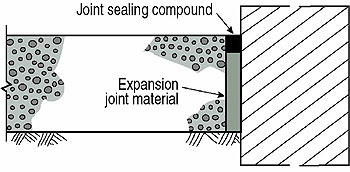

This helps to prevent cracking and damage to the concrete surface. The expansion joint typically consists of a compressible filler material, such as cork, rubber, or foam, that is placed between two concrete slabs.

The filler material is flexible and provides a space for the concrete to expand into, reducing stress and preventing cracking.

This foam is also called isolation strip material

This foam is also called isolation strip materialhow often should you put expansion joints in concrete?

The frequency of expansion joints in concrete depends on several factors, such as the size of the concrete slab, the climate, and the expected movements due to temperature and moisture changes.

Here are some general guidelines for determining the spacing of expansion joints:

- For residential slabs, expansion joints should be placed every 8 to 12 feet.

- For commercial or industrial slabs, expansion joints should be placed every 15 to 20 feet.

- For large concrete structures, such as bridges and parking garages, the spacing of expansion joints can be determined by dividing the total length of the structure by 30 to 40 feet.

- In areas with extreme temperature changes, such as desert regions, the frequency of expansion joints may need to be increased to account for the larger expansion and contraction movements.

The American Concrete Institute (ACI) provides guidelines for installing concrete expansion joints in their publication "ACI 224.3R-95 Joints in Concrete Construction." According to these guidelines, the following factors should be considered when installing concrete expansion joints:

- Climate: The frequency and spacing of expansion joints in concrete slabs should be determined based on the climate and weather conditions in the area, including the expected temperature and moisture changes.

- Slab size: The size of the concrete slab is a factor in determining the spacing of expansion joints. Larger slabs will require more expansion joints than smaller slabs.

- Type of filler material: The type of filler material used in the expansion joint is important for both the performance of the joint and the safety of the users. The filler material should be flexible, compressible, and durable, and it should not break down or become brittle over time.

- Placement of joints: Expansion joints should be placed in a straight line and should be perpendicular to the direction of the anticipated movement. They should also be placed at the same level as the surface of the concrete slab.

- Joint width: The width of the expansion joint should be wide enough to accommodate the expected movement, but not so wide as to allow the concrete to crack or deform. The ACI recommends a joint width of 1/4 to 1/2 inch.

It is important to follow the ACI guidelines when installing concrete expansion joints to ensure that the concrete slab remains strong, durable, and safe.

Consultation with a professional engineer or contractor is recommended to determine the specific requirements for a particular project.

Where do you put expansion joints?

Expansion joints in concrete are typically placed at regular intervals along the length or width of a concrete slab.

These are some basic guidelines for placing expansion joints in concrete:

- At control joints: Expansion joints can be placed at the same location as control joints, which are also placed in concrete to control cracking.

- At the perimeter of the slab: Expansion joints can be placed along the perimeter of the concrete slab to allow for expansion and contraction movements.

- Along the length of the slab: Expansion joints can be placed at regular intervals along the length of the concrete slab to accommodate movements in that direction.

- Along the width of the slab: Expansion joints can be placed at regular intervals along the width of the concrete slab to accommodate movements in that direction.

Are concrete expansion joints necessary?

Concrete expands and shrinks with changes in moisture, humidity, and temperature. The overall tendency is for it to shrink, which can cause cracking at a very early age.

Although shrinkage cracking doesn't usually affect the integrity of the concrete, the irregular cracks aren't pretty to look at.

Installing expansion joints in concrete permit independent horizontal and vertical movement between adjoining parts of the structure and help minimize cracking when such movements are restrained.

Concrete isolation joints, or expansion joints, separate or isolate the concrete from other parts of the building structure like walls, footings, columns and piers.

A concrete expansion joint is also used to separate a concrete driveway or patio from a garage slab, sidewalk, stairway, light-pole or any other point or restraint.

concrete expansion joint materials

The materials used for expansion joints are asphalt-impregnated fiber sheeting. You can buy these 4' x 8' sheets and cut them to the width you need or you can buy pre-cut strips that are 4" or 6" wide by 10' long.

We usually use a spray adhesive to attach the material to the wall, you can also use small concrete nails or caulking.

Another popular expansion or isolation joint material is Iso-strip-off. This compressible foam strip comes in rolls 50' long and multiple widths from 3", 4", and 6".

We use 3M stick-on spray to attach the foam to the wall, you can also use small concrete nails or caulking.

Here are five common materials used for concrete expansion joints:

- Cork: Cork is a natural, sustainable material that is often used as a filler material in concrete expansion joints. It is flexible, compressible, and durable, and it provides good resistance to moisture and temperature changes.

- Rubber: Rubber is another common material used for concrete expansion joints. It is flexible and provides good resistance to moisture and temperature changes. Rubber is also easy to install and does not break down over time.

- Foam: Foam is a lightweight, flexible material that is often used as a filler material in concrete expansion joints. It is easy to install, and it provides good insulation against moisture and temperature changes.

- Neoprene: Neoprene is a synthetic rubber material that is often used for concrete expansion joints. It is flexible, durable, and resistant to moisture and temperature changes.

- Asphalt-impregnated fiberboard: Asphalt-impregnated fiberboard is a rigid material that is often used as a filler material in concrete expansion joints. It provides good resistance to moisture and temperature changes, and it can be easily cut to fit the desired joint width.

There are others, Most of the time the choice of material will depend on the specific requirements of the project, such as climate, concrete type, and slab size.

expansion joint filler material

The most commonly used expansion joint filler material is flexible and durable, providing good resistance to moisture and temperature changes. Some of the most popular materials used as expansion joint fillers include:

- Elastomeric sealants: Elastomeric sealants, such as silicone or polyurethane, are often used to fill concrete expansion joints. They are flexible, durable, and provide good resistance to moisture and temperature changes.

- Pre-molded expansion joint filler: Pre-molded expansion joint filler is a ready-to-install product that is made from materials such as rubber, silicone, or polyurethane. It is flexible, durable, and provides good resistance to moisture and temperature changes.

- Bituminous materials: Bituminous materials, such as asphalt or tar, are often used to fill concrete expansion joints. They are durable, flexible, and provide good resistance to moisture and temperature changes.

I usually use a self-leveling caulking to fill expansion joints. The caulking makes a good seal and prevents water from getting in the joint.

Take a look at the video below to see how I fill expansion joints:

Taking the time to install expansion joints will be well worth the effort it takes. Reducing the amount of random or shrinkage cracking in your slab will make it look much nicer.

To help further reduce random cracks in concrete read about concrete construction joints and concrete contraction joints.