How To Resurface or repair

your existing concrete

with a concrete overlay in 2025

Updated: November, 2024

Author: Mike Day

A concrete overlay can give your old, worn, or damaged concrete a brand new look.

Overlays can be applied from feather edge up to 1 inch thick in some cases. They can be finished smooth, broom finished, or even colored & stamped.

Application is done with a trowel, squeegee, or a gauge rake & smoother. Making it easy to give just about any concrete surface a brand new appearance at a much lower cost than removing and re-pouring new concrete.

concrete overlay flooring

In the picture below, we're using a self-leveling concrete overlay that's about 1/8" thick to resurface an existing concrete floor.

The concrete floor was stained & damaged and the owner wanted a brand new surface that was easier to clean. We used a bag mix self leveling overlay called FLAT TOP to solve this problem.

Flat Top is a polymer modified concrete overlay designed to resurface concrete floors just like this one. It's applied at 1/8" thick and one bag covers 50 square feet.

After it cured we applied a clear concrete sealer to finish and protect the floor.

In the pictures below, I'm using a concrete overlay to resurface and level a concrete floor in a restaurant.

We ground the concrete to clean it, fixed any cracks, applied the primer, and poured the self-leveling mix onto the floor to smoothen the surface.

Afterwards we applied a new epoxy floor to finish it off.

See the process and the finished floor HERE.

The self-leveling overlays are very fluid and only need a little "help" to spread and apply.

This floor was about an inch out of level before we applied the overlay. Afterwards it was nearly perfect.

That's me installing a self leveling concrete overlay

That's me installing a self leveling concrete overlayconcrete overlay mixes for different applications

What is a concrete overlay?

A concrete overlay is a specially designed, thin layer of polymer modified concrete used to resurface or repair existing concrete. They can be applied from feather edge thin up to 2" thick in some cases. Overlays can be stamped, broom finished, or left smooth.

Most all manufactures of concrete overlay products have their own proprietary blends.

All you really need to know is they're a blend of Portland cements, various aggregates and polymer resins that are very strong.

It's the polymers in these overlays that make them special. The polymers are the "glue" that help make them very strong and provide a tenacious bond to properly prepared concrete.

does a concrete overlay last?

Before the concrete overlay

Before the concrete overlayA concrete overlay will last a very long time if the surface it's being applied to is prepared properly.

The existing surface has to be clean and sound with no loose or flaking areas of concrete.

Deep spalling and cracks have to be repaired first. (This is how to do that)

You may have to treat the existing concrete first with a concrete densifier and hardener if your concrete is really old and porous.

And... you have to mix and apply the concrete overlay according to the manufactures specifications.

Then you need to seal it with a concrete sealer to protect it.

If you do all of that, your concrete overlay will last a long time.

After applying a thin layer of concrete overlay

After applying a thin layer of concrete overlayWe installed a thin coating of concrete overlay to brighten up and restore the finish on this pool deck.

The process included:

- Thoroughly pressure wash the existing concrete to clean it, then let it dry.

- Dampen the concrete and squeegee on the first layer of concrete overlay to prime the surface

- After that was dry, slightly dampen again and squeegee on another thin layer, then immediately drag a broom across the "wet" overlay to texture it with a broom finish

- Let the entire surface completely dry overnight

- Apply 2 coats of concrete sealer (Done!)

This concrete was just worn looking and didn't need any repair. If it did need some crack or spalling repair we would have done that after pressure washing.

how to resurface damaged concrete with a concrete overlay

PREPARE THE CONCRETE - The above concrete apron has some damage caused by de-icing salts being used in the winter. We call this type of damage spalling.

The top layer of concrete, usually about 1/8", peels from the surface.

We prep the concrete a couple ways. Either by lightly grinding the concrete or by pressure washing it. Sometimes both!

On this one we used a 5" diamond grinder/with vacuum attached, and removed all the loose concrete. We ended up grinding the entire surface to get back down to the good concrete.

About 1/8" of the surface was removed. Then we cleaned any dust and applied the liquid primer product from the concrete overlay company.

PRODUCT SELECTION - I chose to use a concrete overlay called "Trowel Mix" to repair and broom finish the concrete.

It's a very easy to use "just add water" concrete overlay that can be troweled on from 1/16" to 3/8" thick.

APPLYING THE OVERLAY - I mix the overlay in a 5 gallon bucket with about 5 quarts of water for 2 minutes.

I pour some of the mix on the primed concrete and start troweling a thin layer across the surface.

As soon as I'm troweling it to the level I want it, I can broom finish it and leave it alone.

The next day I applied a concrete sealer to protect it and done. Trowel mix can be used for driveways, pool decks, sidewalks, and patios.

how much does a concrete overlay cost?

When you look at the cost of concrete overlay material, it's going to depend on what your using it for.

There's concrete overlays for very thin micro-topping finishes of 1/16" or less, most of the time this is used to get a smooth appearance. There's overlays made for resurfacing 1/8" to 3/8" for broom finish and there's overlays for stamped concrete appearances.

There's other overlay material used just for deep repairs and others used for getting a polished concrete floor look.

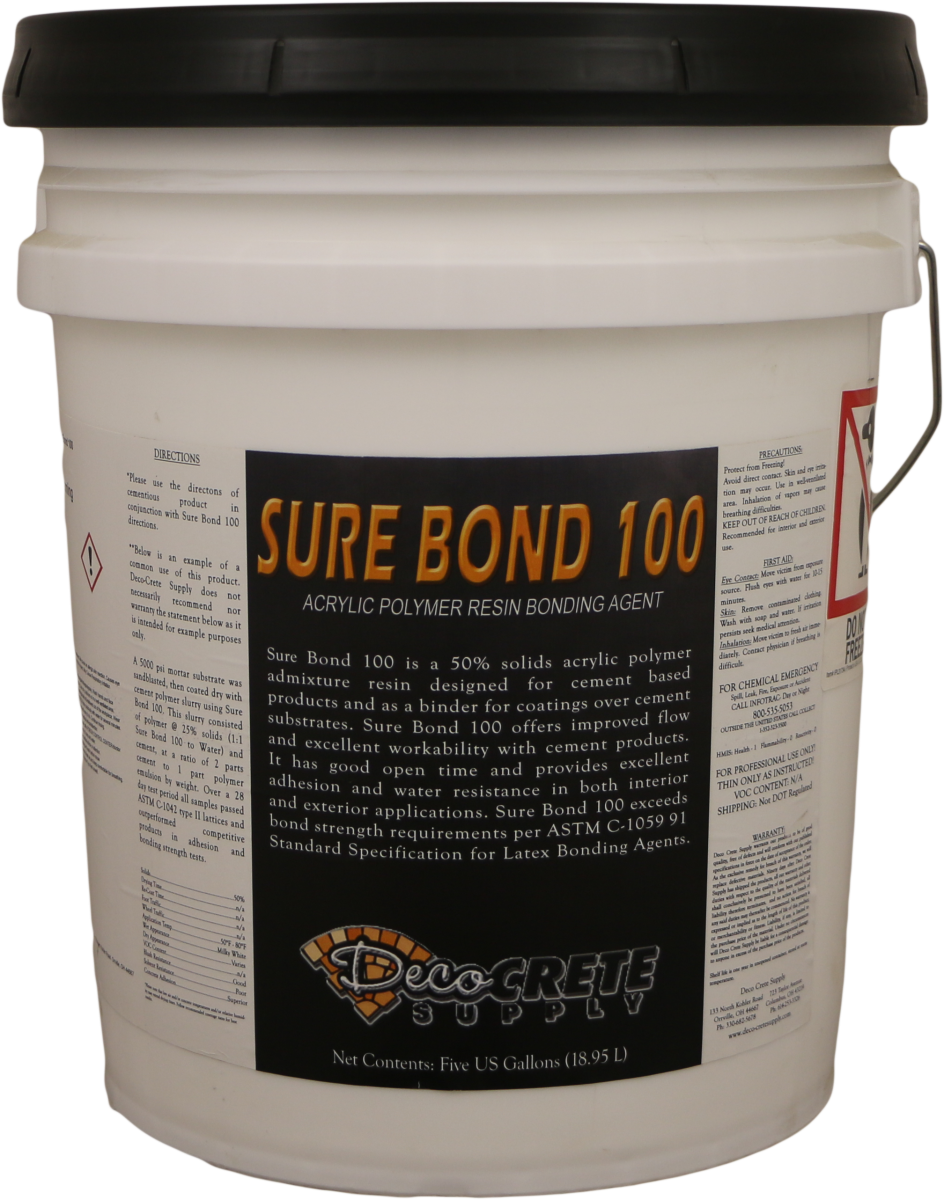

At Deco-Cretesupply.com a bag of micro-topping concrete overlay is about $80.00 per 37 lb. bag, and will cover 300 - 500 square feet.

The 1/8" - 3/8" bag of concrete overlay is about $36.00 per 50 lb. bag, it covers 48 square feet at 1/8" thick.

A 50 lb. bag of self-leveling overlay mix is about $30.00 and covers 50 square feet at 1/8" thick.

Labor prices will vary depending on the amount of prep, repair, and type of overlay finish you're going after.

Smooth and broom finishes will generally run $5 - $10 dollars per square foot and stamped overlays can run between $10 - $20 dollars per square foot. These prices include both labor and materials.

what can i use for concrete overlay?

Deco-Cretesupply.com has a very user friendly line of concrete overlay bag mixes.

They include:

- Trowel mix - Used for overlay applications like broom finish and skip trowel finish.

- Flat Top - Can be used as a self leveling underlayment mix, concrete repair, and resurfacing.

- Pro Micro-Top - A micro-thin concrete resurfacer for most any concrete surface, can be colored and stained.

- Stamp Mix- Used for stamped concrete finished surfaces.

- Spray Mix - Used for smooth finishes, knockdown finish, stenciling, and texture coats

will concrete overlay crack?

In most cases if the sub-base prep is done correctly and any damaged concrete is repaired properly then the concrete overlay will not crack.

Any existing cracks in the concrete have to be fixed like this or there's a chance the repaired crack could transfer up through the overlay.

If the existing concrete you're about to overlay is still moving (settling or heaving) then the new concrete overlay will most likely crack right over the repaired cracks.

Some concrete overlays have to be kept damp as they cure so they don't cure too fast. If a concrete overlay cures too fast (like being in the hot sun) it could crack from rapid curing.

This is more likely to happen on 1/4" thick and thicker overlays.

how thick should a concrete overlay be?

The thickness of a concrete overlay will vary for these applications:

- Resurfacing an interior concrete floor - 1/16" - 1/8"

- Resurfacing a concrete walk, driveway, patio, or pool deck - 1/8" - 3/8" (includes stampable)

- Self-leveling underlayment - 1/8" up to 2"

- Self-leveling overlay (including polishable) - 1/4" up to 2"

These are just general guidelines and what I've done the most of.

Every manufacturer's bag of overlay mix has a minimum and maximum thickness labeled right on the bag.

If you have a project where the overlay material is going to be 2" thick or more, some mixes can have pea-stone added to them for the thicker applications.

what's a good exterior concrete overlay product for a driveway?

If you have a concrete driveway that needs to be resurfaced then Stone Edge Surfaces Trowel Mix is an excellent overlay you can use to achieve a brand new looking broom finish.

It's made specifically for resurfacing concrete driveways, patios and sidewalks.

It comes in a white or grey base that can be tinted with integral pigment when you mix it.

The added micro polypropylene fibers give it added flexural and tensile strength plus more durability than other overlay mixes.

The mix has a blend of flexibilizers, plasticizers, and finishing agents that help minimize any freeze and thaw spalling & cracking on the surface.

What's a good concrete overlay for countertops?

If you're going to use a concrete overlay on your countertops, you're either going to go very thin and smooth or stamp it with a pattern.

For thin and smooth - Use Pro Micro Top Mix, it comes in light grey and white. You can dye it with color or stain it after it's cured.

For a countertop with a texture or stamped - Use Stamp Mix, this can go on up to 3/8" if you want to stamp a design into it. Can also be colored or stained.

Watch us use a concrete overlay to repair and resurface this patio slab.

In the video below, we had to repair some spalled concrete on this concrete patio before we could overlay it.

The video will show you, step by step, what it takes to resurface a damaged, spalled, or worn concrete patio slab.

Here's an example of how to use a concrete overlay to repair a set of stairs.

|

|

These stairs were in bad shape and were supposed to get demolished & replaced with a new set of poured in place concrete stairs.

When the owners got the final quote on what it would cost to replace the entire set of stairs and part of the frost wall you see in the background, they opted for a concrete overlay instead.

My company, Day's Concrete Floors, Inc. was called in to see if we could repair, resurface, and overlay the stairs to save them and make them look new again.

Well, they were pretty banged up but they were structurally sound.

We ground off some paint and profiled the smoother parts with a 4" handheld grinder. The rest of the stairs we used a high velocity pressure washer to clean and profile the concrete.

We re-formed the stair treads, applied the concrete overlay product in multiple applications and the end product was a new set of stairs at about 1/5 the cost of replacing them.

Can i have a decorative concrete overlay?

|

Yes, this decorative overlay replaced old carpet and tile in a hotel lobby. The project totaled 4500 sq. ft. of stamped and hand carved stones. The overlay material was a total of 1/4 inch thick over an old concrete floor. An excellent stampable overlay mix is STAMP MIX. |

|

This stamped concrete overlay was installed over an old, worn concrete patio that sloped towards the house. We resurfaced the concrete with our overlay, stamped a cobblestone pattern into it, and sloped the overlay away from the house to shed water. |

A spray down or sprayed on concrete overlay is great when you need some texture on the surface for slip-resistance or if you use a stencil to create a pattern like the one below.

Concrete resurfacing using an overlay can make an old, cracked and pitted concrete patio look like new again.

On this patio, I repaired the small cracks, lightly ground the surface, applied the overlay with a hand trowel at about 1/16 inch thick, then dragged a broom across the overlay to give it a broom finished look.

I would use the trowel mix concrete overlay if you are going to diy this type of project.

After After |

Watch and learn how we resurface a concrete patio like this!

A quick recap:

As you can see, concrete overlays can be used for many kinds of projects.

You can use them to repair concrete, for ultra thin toppings, for decorative stamping and staining, and to level a floor that's tipped or pitched the wrong way.

An overlay can be much less expensive than a complete demo and replace with new concrete.

If you're thinking of trying this yourself, my advice is practice on some hardy board or old concrete you don't care about.

We've been trained to use these products. We mostly use Walt Tools and Elite Crete Systems brand.

They do have training classes that will teach you how to use their concrete overlay products and provide you with support if you have questions.

Of course, hiring a professional, is always a good choice also.

How to use self leveling concrete to level a floor.