What is a contraction joint in concrete

A concrete contraction joint, also known as a control joint, is a type of joint in concrete slabs that helps to control cracking caused by the dimensional changes that occur as concrete dries and cures.

It is typically formed by saw cutting or hand tooling a groove into the concrete surface and filling it with a flexible material, such as a pre-molded strip or a joint sealant, to allow the concrete to shrink and expand as needed without cracking.

The depth of the groove and the distance between the joints are typically specified by building codes and engineering standards to ensure adequate control of cracking.

why do you need contraction joints in concrete?

Contraction joints, also known as control joints, are needed in concrete because concrete is a highly durable material but it can also be prone to cracking as it dries and cures.

Concrete contracts as it dries, and if this contraction is not properly managed, it can lead to cracking in the surface of the concrete.

Cracks in concrete can weaken the structure, allow water and other substances to penetrate the surface, and can also create a visually unappealing appearance.

Contraction joints are used to control the location and width of cracks in concrete by creating a weakened plane in the concrete where it is more likely to crack.

By controlling the location of cracks, the joints help to prevent cracks from spreading and causing structural damage to the concrete.

how do you make concrete contraction joints?

I'm using a jointer tool to cut in a contraction joint

I'm using a jointer tool to cut in a contraction jointThere are several methods for creating contraction joints in concrete, including the following:

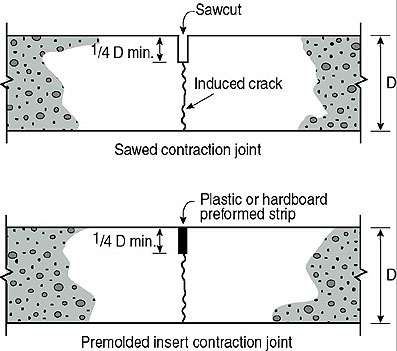

- Saw cutting: This method involves using a saw, such as a diamond blade saw, to cut joints into the concrete surface at predetermined intervals. The depth and width of the saw joint can vary, but they are typically cut to a depth of one-quarter to one-third of the thickness of the concrete slab.

- Pre-molded strips: This method involves installing pre-molded flexible strips made of rubber, plastic, or other materials into the concrete prior to it setting. As the concrete cures and contracts, the strips allow for controlled cracking along the line of the strip.

- Tooling: This method involves using a special tool, such as a hand-held jointer or groover, to create a or score line or "joint" in the concrete surface. As the concrete dries and contracts, it cracks along the joint created by the tool.

In general, the method used to create contraction joints will depend on the type and size of the concrete pour, as well as the engineered building plans.

Regardless of the method used, it's important to carefully plan the placement and spacing of contraction joints to ensure that the concrete cures in a controlled manner, without cracking or causing structural damage.

Below you'll see what a contraction joint may look like and how it induces a crack inside the joint.

Here are two common methods used to install a concrete contraction joint

Here are two common methods used to install a concrete contraction jointhow far apart should contraction joints in concrete be?

The American Concrete Institute (ACI) provides guidelines for the spacing of contraction joints in concrete through its ACI 224R-01 Guide to the Use of Control Joints in Concrete Construction report.

According to the ACI, the recommended spacing of contraction joints is dependent on the concrete's type and thickness, and the environment in which it is placed.

For normal weight concrete slabs that are 4 inches or less in thickness, the ACI recommends spacing contraction joints at intervals of 10 to 15 feet. For thicker slabs, the spacing should be reduced.

The ACI also recommends spacing contraction joints more closely in areas where the concrete is subject to heavy loads or large temperature changes.

Here we are using an early entry Soff-Cut saw to install contraction joints about every 10 feet apart in a concrete slab that's 6 inches thick.

what's the difference between a contraction joint and an expansion joint?

Contraction joints and expansion joints are both types of joints in concrete that are used to control cracking and reduce stress on concrete structures. However, they serve different purposes and are used in different ways.

Contraction joints, also known as control joints, are placed in concrete to control where cracking occurs due to the drying and shrinking of concrete as it cures.

They are designed to create a weakened plane in the concrete surface, so that when the concrete contracts, it cracks along the joint instead of randomly throughout the slab.

The goal of contraction joints is to create smaller, more manageable cracks that are less likely to compromise the structural integrity of the concrete.

Expansion joints, on the other hand, are used to accommodate thermal expansion and contraction of concrete structures.

They are designed to separate concrete sections that are subjected to different temperature changes, such as when a concrete structure extends across a large area or when it is exposed to direct sunlight.

Expansion joints are typically filled with a flexible material, such as rubber or neoprene, that allows the concrete sections to move relative to each other without cracking.

In summary, contraction joints are used to control cracking in concrete due to drying and shrinkage, while expansion joints are used to accommodate thermal expansion and contraction.

Both types of joints are important components of concrete structures, and they are typically specified by a professional engineer or concrete contractor based on the specific requirements of the structure and the environment in which it is located.

where should contraction joints be located?

Some general guidelines for placement of contraction joints in concrete include:

- At regular intervals: Contraction joints should be placed at regular intervals along the length and width of the concrete slab. The spacing of the joints is typically determined by the mix design and thickness of the concrete, the weight applied, and the intended use of the concrete.

- Along structural elements: Contraction joints should be placed along structural elements, such as beams and columns, to help prevent cracking in these areas.

- At changes in direction: Contraction joints should be placed at changes in direction in the concrete, such as at corners and curves, to help control cracking in these areas.

It is important to note that the placement of contraction joints in concrete is a critical design consideration, and the correct placement can be determined by a professional engineer, concrete contractor, or architect with experience in designing concrete structures.

follow this rule of thumb for joint depth

To achieve the best results, there are specific guidelines that should be followed for different types of contraction joints.

- For example, for tooled or grooved joints, the depth of the joint should be 1/4 of the slab thickness, with an edge radius of 1/8 inch for interior floors and 1/4 to 1/2 inch for exterior slabs.

- For wet-cut sawcut joints, the depth should be 1/4 the slab thickness or a minimum of 1 inch, with a tolerance of ±1/4 inch.

- For joints installed with an early-entry dry-cut saw, the joint depth should be 1-1/4 inch for slabs with thicknesses up to 9 inches, with a tolerance of ±1/4 inch.

- For thicker slabs or fiber reinforced slabs, the saw cut depth may need to be increased to ensure joint activation.

These guidelines are important to follow to ensure that contraction joints are effective in preventing random cracking in concrete floors and slabs.

follow this rule of thumb for joint spacing

To achieve better crack control, it's recommended to keep the maximum distance between joints limited to 2 to 2.5 times the slab thickness.

- For a 6-inch-thick slab, this means limiting the maximum joint spacing to 12 to 15 feet. Exceeding a joint spacing of 15 feet for a 6-inch-thick slab will increase the risk of random or out-of-joint cracking.

- For a 4 inch thick slab, this means limiting the maximum joint spacing to 8 to 10 feet. Exceeding 10 feet for a four inch thick slab can increase the chances of random cracks developing outside the joints.

- For sidewalks and driveways, transverse contraction joints should be spaced at intervals roughly equal to the slab width. For 4-inch-thick sidewalks and driveways wider than 10 feet, it's recommended to add a longitudinal contraction joint along the center and keep the panels as square as possible.

In general, reducing the joint spacing will help reduce the risk of random cracking and improve aggregate interlock, which enhances the load transfer capacity and helps maintain better vertical alignment across joints.

in conclusion:

In conclusion, contraction joints are crucial in concrete construction as they help control cracking. There are various methods of forming contraction joints, including saw cutting, grooving, and plastic strip insertion.

The timing and depth of the cut are essential to ensure that the slab cracks where it is intended to. The spacing of the joints depends on the concrete mix and its shrinkage potential. Proper placement of the joints is also critical to avoid problems.

Control joints should be straight and continuous, and efforts should be made to avoid re-entrant corners within the slab. Reinforcement should not extend through contraction joints to prevent uncontrolled cracking. Proper jointing patterns, spacing, and placement are key to ensuring a successful concrete project.

To help further reduce cracking in concrete read about concrete expansion joints and concrete construction joints.