what is a concrete construction joint?

A construction joint in concrete is a deliberate break or interruption in the continuous pour of concrete that allows for the consolidation of concrete and helps control cracking and separating due to shrinkage.

Simply, they're stopping and starting points used when you don't pour the whole slab, floor, sidewalk, or driveway all at the same time.

where are construction joints placed in concrete?

Construction joints are usually placed where one concrete pour stops and a new pour butts up against it the next day or at a later date.

For example, a 100 foot long sidewalk is poured in three separate sections. The first section is poured 33 feet long by 5 feet wide. Where the pour stops and the next section starts is a "construction joint".

The next day the form is removed and another 33 foot long section is poured using a 2x4 form to stop the pour, hence another construction joint.

The third day the remainder 34 foot section is poured and the sidewalk is complete. This 100 foot long sidewalk was completed using two construction joints.

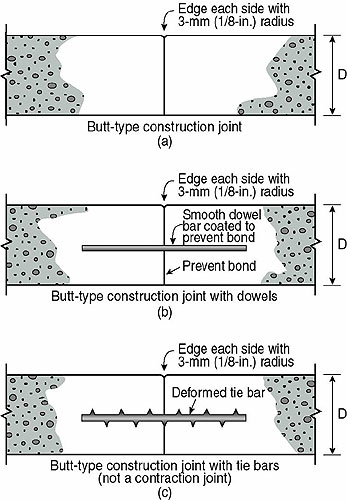

the cross section of a construction joint looks like this

Concrete, when drying, has a natural tendency to shrink. For large pours or long narrow pours, like sidewalks, installing construction joints at preplanned locations will help minimize random cracking in the concrete.

Concrete construction joints are formed using a wood form, steel keyway, or plastic bulkhead. In some cases the bulkheads are also used as screed rails for the next pour.

For light duty slabs it's a good idea to use the smooth dowel method. For slabs with heavier traffic, some sort of keyway and dowel or thickening the edge along with dowels would be better to transfer the load from one slab to the other.

Using keyway construction joints was once the preferred method, but has since been found not to be as effective as dowels or diamond keyed joints.

The reason for this is after the concrete cured, each slab shrinking away from each other opened the construction joint enough so the keyway edge proved not to be very effective and more prone to fail.

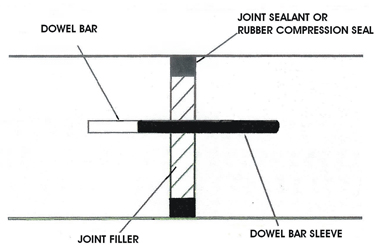

For dowels to be effective they must be aligned properly. Dowels must be perpendicular to the joint both horizontally and vertically or joint deterioration can occur.

Smooth dowels work best. The concrete must be able to move freely along the dowel as it cures and shrinks.

Drilling holes through the bulkhead and sliding the dowel into the fresh concrete is one method. Using dowel sleeves nailed to the inside edge of the bulkhead is another method used to install dowels.

Using diamond dowels for construction joints are a newer and very effective method for controlling load transfer and at the same time allowing the slab to shrink in two directions, eliminating all restraint.

Installing diamond dowels is as simple as nailing the plastic sleeve onto your form before you pour, then after you strip the form, insert the metal diamond into the plastic sleeve.

Making sure the concrete is properly consolidated at the construction joint by using a hand held vibrator will help insure the dowel or diamond method properly transfers load between placements.

Concrete construction joints are just one way to help minimize random cracking in concrete floors. To help further reduce cracking in concrete floors read about concrete contraction joints and concrete expansion joints.

You can learn all about how to fix cracks in concrete floors by going to epoxy concrete repair.

Leave concrete construction joints and go to concrete control joints