concrete vs cement: understanding the difference

Mixing Things Up: Understanding the Key Differences between Concrete and Cement

Understanding the difference between cement and concrete

Understanding the difference between cement and concreteWhat's the difference between concrete and cement?

Cement is a binding material used in construction, while concrete is a composite material consisting of aggregate (such as sand, gravel, or crushed stone), water, and cement.

Cement serves as the glue that holds the aggregate together, while concrete is the finished product that results from mixing cement with aggregate.

In other words, cement is one of the components that makes up concrete, but it is not the same thing as concrete.

Concrete is stronger and more durable than cement alone, and it is used in a variety of construction applications, including building foundations, walls, roads, and bridges.

The basics of concrete

The basic fundamentals of concrete include the following:

- Mix Design: The proportions of cement, water, aggregate, and any additional ingredients are carefully measured to produce a concrete mix with the desired strength and workability.

- Hardening Process: After mixing, the concrete sets and hardens through a chemical reaction called hydration. This process creates strong and durable bonds between the cement and aggregate.

- Compressive Strength: Concrete's compressive strength is one of its most important properties and determines its ability to withstand heavy loads. The compressive strength of concrete increases as it cures over time.

- Porosity: Concrete is a porous material, which means it contains small air pockets and is therefore susceptible to moisture and freeze-thaw damage. To reduce porosity, concrete is often treated with waterproofing agents.

- Durability: The durability of concrete depends on several factors, including its mix design, the quality of the materials used, the curing process, and the environment in which it is placed.

- Workability: Workability refers to the ease with which concrete can be mixed, placed, and compacted. Workability is affected by the water-cement ratio, the size and shape of the aggregate, and the type of admixtures used.

- Sustainability: The use of recycled materials, such as crushed glass or fly ash, can help to make concrete more environmentally friendly and sustainable.

These are some of the basic fundamentals of concrete, which are important for understanding how concrete behaves and how it can be used in construction.

The basics of portland cement

The basic fundamentals of Portland cement include the following:

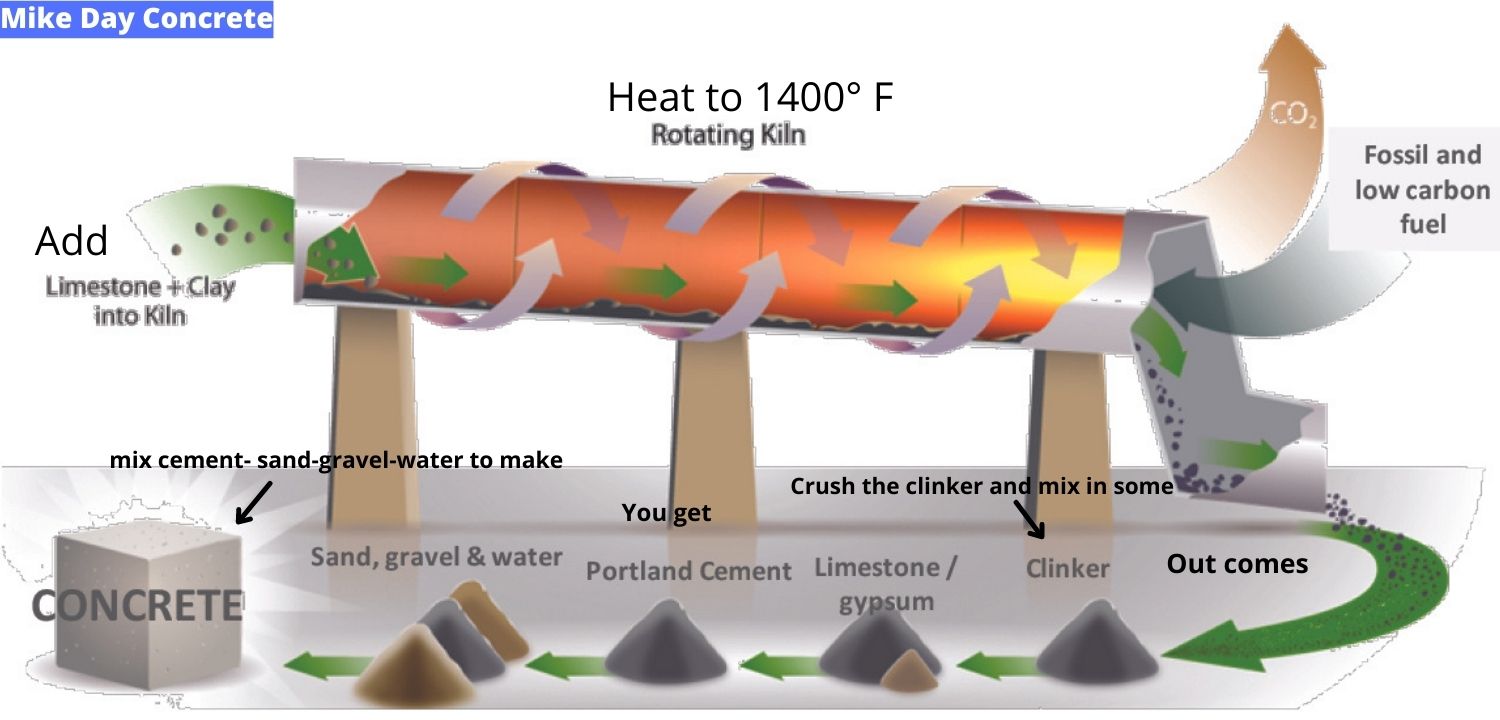

- Composition: Portland cement is made from a mixture of limestone, clay, and other materials that are heated to high temperatures to form clinker. The clinker is then ground into a fine powder to produce Portland cement.

- Hydration: When Portland cement is mixed with water, it undergoes a chemical reaction called hydration, which causes it to harden and gain strength over time. This reaction produces compounds known as hydrates, which give concrete its strength and durability.

- Setting Time: Portland cement has a characteristic setting time, which is the time it takes for the mixture of cement and water to harden into a solid mass. The setting time of Portland cement can be influenced by temperature, humidity, and the type of admixtures used.

- Strength Development: The strength of Portland cement concrete develops over time as the hydration reaction continues. The rate of strength gain depends on factors such as the mix design, curing conditions, and the type of Portland cement used.

- Durability: The durability of Portland cement concrete depends on several factors, including the mix design, the quality of the materials used, the curing process, and the environment in which it is placed.

- Sustainability: The production of Portland cement is a major contributor to greenhouse gas emissions, and efforts are being made to develop more environmentally friendly alternatives. This includes the use of alternative binders, such as ground granulated blast-furnace slag, and the use of supplementary cementitious materials, such as fly ash.

These are some of the basic fundamentals of Portland cement, which are important for understanding how it behaves and how it can be used in construction.

How is cement made?

when should i use concrete or cement?

Concrete and cement are both building materials that can be used for construction projects, but each has its own unique properties and uses.

Concrete is typically used when a strong and durable building material is required. It is ideal for constructing buildings, bridges, roads, and other infrastructure projects that require a solid and long-lasting structure.

Cement, on the other hand, is used as a binding material in applications such as mortar, grout, and concrete. It is also used as a base material in stucco and other decorative finishes.

In summary, concrete should be used when a strong and durable building material is needed, while cement should be used when a binding material is required.

The specific choice between concrete and cement will depend on the requirements of the specific project, including the type of structure being built, the environment in which it will be placed, and the desired properties of the final product.

is cement stronger than concrete?

Cement and concrete are not the same thing and cannot be compared in terms of strength in isolation.

Cement is a fine powder that serves as the binding agent in concrete. When cement is mixed with water, it undergoes a chemical reaction called hydration, which causes it to harden and gain strength over time.

Concrete, on the other hand, is a composite material that consists of a mixture of cement, water, and aggregate (such as sand, gravel, or crushed stone). The combination of these materials creates a material that is stronger and more durable than cement alone.

In other words, concrete is stronger than cement, but cement is an essential component of concrete that provides its binding and strength-enhancing properties.

are sidewalks made of concrete or cement?

Sidewalks are typically made of concrete. Concrete is a composite material that consists of a mixture of cement, water, and aggregate (such as sand, gravel, or crushed stone).

This mixture is poured into a mold and allowed to harden, creating a strong and durable surface that is suitable for a variety of applications, including sidewalks.

Cement, on the other hand, is a fine powder that serves as the binding agent in concrete. It is not typically used on its own for sidewalks or other infrastructure projects due to its lack of strength and durability.

concrete vs cement vs mortar - what's the difference?

Concrete, cement, and mortar are all building materials that are used in construction projects, but each has its own unique properties and uses.

Concrete is a composite material that consists of a mixture of cement, water, and aggregate (such as sand, gravel, or crushed stone). The combination of these materials creates a material that is strong, durable, and ideal for constructing buildings, bridges, roads, and other infrastructure projects.

Cement is a fine powder that serves as the binding agent in concrete. When cement is mixed with water, it undergoes a chemical reaction called hydration, which causes it to harden and gain strength over time. Cement is also used as a binding material in applications such as mortar and grout.

Mortar is a mixture of cement, water, and sand that is used as a binding material in construction projects, particularly in masonry work. It is typically used to bond bricks, stones, or other masonry units together.

Unlike concrete, mortar is not used to provide structural support; instead, it serves as a filler material that holds masonry units in place.

In summary, concrete and cement are both building materials that have different properties and uses, while mortar is a specific type of binding material used in masonry work.

characteristics of good concrete

Good quality concrete has a few specific characteristics that you should understand:

- Strong - when fully cured it has a high compressive strength

- Durable - can withstand freezing & thawing temperatures as well as very hot weather

- Workable - when being placed it's not too wet or too dry. It's ingredients are proportioned and mixed properly so it consolidates while it's poured in place.

- Low shrinkage - Not using too much water to mix and place the concrete

In general, using the least amount of water necessary to mix and place the concrete produces a higher quality concrete. This assumes the concrete is properly placed, consolidated, finished, and cured.

what is a good concrete mix design?

There's different concrete mix designs for different kinds of projects. All of them can be considered good if the end result turns out as planned.

A concrete mix design for a highway bridge will be different than a mix design for a residential garage floor. Both are good, they just have different proportions of ingredients (and maybe some other additives included).

Basically, a good mix design includes:

- Good workability

- Good strength

- Highly durable

- Fairly dense

- Good finishability

Concrete mixing ratios can be adjusted according to what you're using the concrete for.

A simple but good concrete mix design is 1 part cement to 2 parts sand to 3 parts stone mixed with as little water an necessary to get the workable mix you need.

See my concrete mixing ratios for 3000 and 4000 psi concrete mix designs.

There's different types of cement

Did you know there's different types of cement?

Here they are:

- TYPE I - A general purpose cement that can be used for most applications

- TYPE II - Moderate sulfate resistance

- TYPE III - High early strength

- TYPE IV - low heat of hydration, slower reacting

- TYPE V - High sulfate resistance, develops strength slower than other types

the difference between cement vs concrete?

The bag of Portland Cement is a dry "fluffy" powder you can use to MAKE concrete. Just add sand, stone and water.

The bag of concrete already has cement, sand, and stone all mixed together "in the bag". You just need to add water and mix it to get concrete.

If you making patio blocks, pouring a small slab, or installing a fence post, you'll want to get the bag of concrete for these type of projects.

Rarely, if ever, will you just use cement to do anything other than make your own concrete from mixing the raw materials (cement, sand, stone, & water).

Learn my concrete mixing ratio for strong concrete.

Discover how old concrete really is.