What is Crazing in Concrete? Your Ultimate Guide

INTRODUCTION:

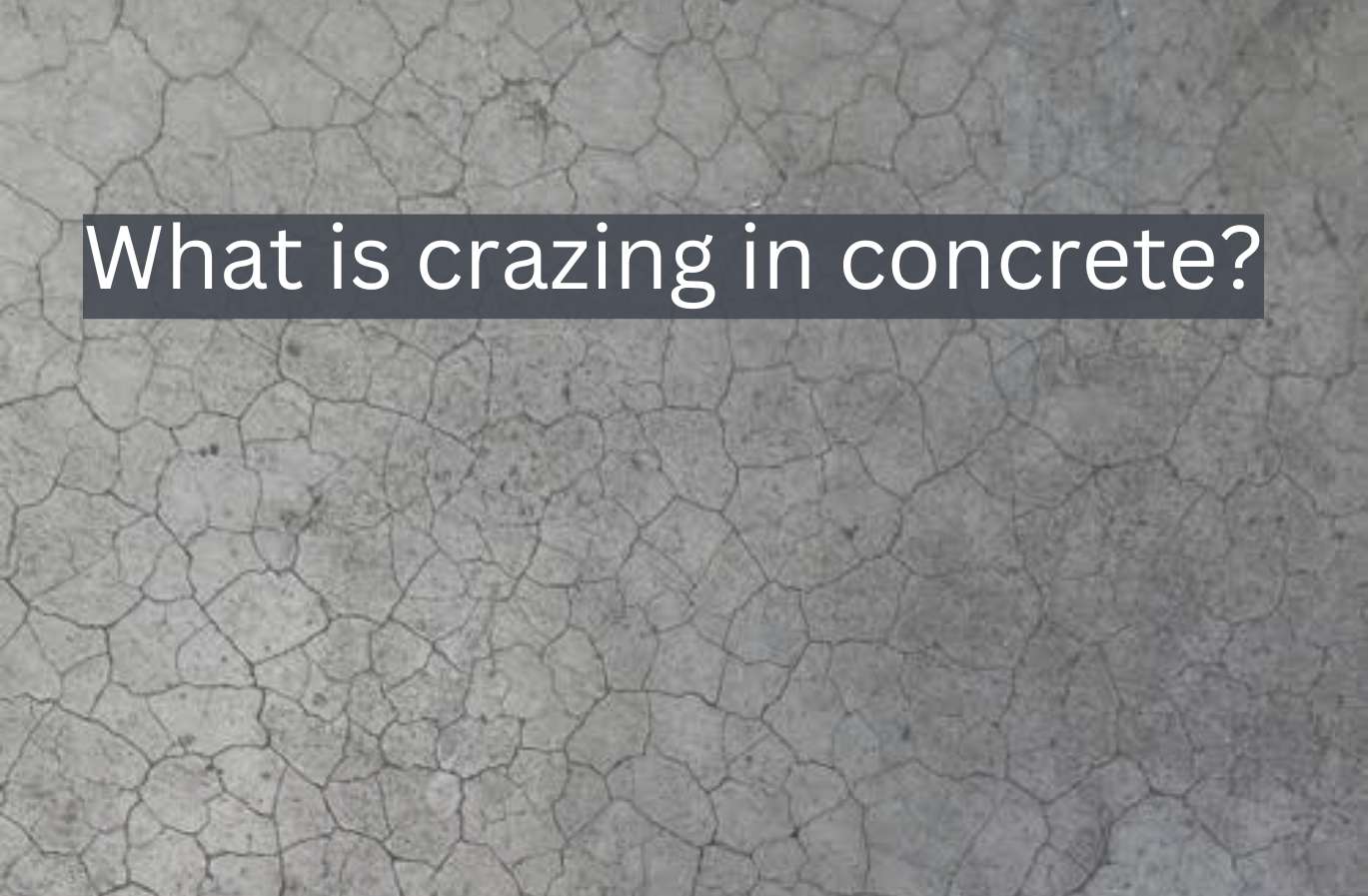

Crazing, a term that may be unfamiliar to many outside the construction industry, is a common phenomenon that can affect the surface of the concrete. If you've ever noticed a network of tiny cracks creating a pattern similar to a roadmap on a concrete surface, then you've seen something called crazing.

While it might appear unsettling, it's essential to understand what crazing truly is, the causes behind it, and its implications for the integrity of the concrete.

What is crazing in concrete: Crazing refers to the development of a network of fine random cracks or fissures on the surface of concrete caused by shrinkage of the surface layer. These surface cracks are rarely more than a few millimeters deep and are generally not structurally significant, meaning they don't typically threaten the stability or integrity of the concrete structure.

Crazing cracks (spider cracking) can be unsightly and may reduce the surface durability of the concrete. The primary concern with crazing is aesthetics. Over time, dirt fine sand can accumulate in these small cracks, making them more visible and potentially detracting from the appearance of the concrete surface.

what causes crazing on concrete

Understanding the causes of crazing can help prevent it in future projects. There are several factors that can contribute to crazing:

- Improper or Insufficient Curing: Curing plays a critical role in the strength and durability of concrete. If the concrete surface dries out too quickly, it can lead to crazing. A properly cured concrete surface retains moisture, allowing the cement hydration process to continue, resulting in a stronger, more durable surface.

- Water-Cement Ratio: A high water-cement ratio in the concrete mix can lead to a weak surface layer and promote crazing. The additional water can lead to increased shrinkage as it evaporates, causing the surface to crack.

- Poor Finishing Techniques: Overworking the surface of the concrete during the finishing process can bring too much water and cement to the surface. This creates a weak, high water-cement ratio layer on the surface, which is prone to crazing.

- Environmental Factors: Rapid evaporation drying due to high temperatures, low humidity, or windy conditions can also cause crazing by pulling moisture out of the concrete too quickly.

how to avoid concrete crazing

Crazing cracks in concrete are generally the result of improper practices during the mixing, pouring, or curing of the concrete, as well as environmental conditions. While these cracks are usually only superficial, they can detract from the appearance of the concrete and may increase its susceptibility to wear and tear over time.

Here are some of the best ways to prevent concrete crazing:

- Optimal Water-Cement Ratio: Use the appropriate water-cement ratio for the project. More water makes the mix easier to work with, but it also makes the set concrete more porous and weaker. The water-cement ratio should be as low as possible to maintain a workable mixture.

- Proper Curing Practices: Ensuring concrete cures properly is crucial. Curing is the process of controlling the moisture loss from the concrete. It can be done by keeping the surface wet with water or a curing compound, or by covering the concrete with an impermeable layer such as plastic sheeting.

- Adequate Finishing: Over-finishing or finishing while bleed water is still present can work an excessive amount of water and cement fines to the surface, leading to a weak surface layer and subsequently crazing. The surface should be finished only after the bleed water has evaporated.

- Use of Proper Mix: The mix should be designed with suitable air content depending on the exposure conditions. The use of supplementary cementitious materials (SCMs) or admixtures can also help in reducing crazing.

- Environmental Considerations: Environmental factors, such as hot sun, wind, or low relative humidity, can cause the surface of the concrete to dry too quickly, leading to crazing. Therefore, it's important to consider environmental conditions when pouring and curing concrete.

- Gradual Drying: If possible, let the concrete dry slowly. This will help prevent the top layer of the concrete from drying and shrinking faster than the bottom layer, a common cause of crazing.

can you fix concrete crazing

Crazing in concrete is generally more of a cosmetic issue than a structural one, as the cracks are usually quite shallow and do not penetrate deep into the concrete. However, if the appearance of crazing on your concrete bothers you, there are ways to mitigate it:

- Cleaning: Regular cleaning of the concrete surface can help minimize the visual impact of crazing. Dirt can accumulate within the fine cracks and make them more noticeable, so regular cleaning can help keep the cracks as invisible as possible.

- Sealing: Applying a high-quality concrete sealer can help reduce the visibility of crazing cracks. The sealer can also help protect the concrete surface from stains and other forms of damage that could exacerbate the appearance of the cracks.

- Resurfacing: If the crazing is widespread and significantly detracts from the appearance of the concrete, you might consider a concrete resurfacer. These products can provide a new surface layer to the existing concrete. It's a more intensive solution but can effectively hide crazing and give a fresh, new look to the concrete.

- Grinding and Polishing: For interior concrete floors, grinding and polishing can help remove the surface layer of the concrete, including any crazing. This process can create a smooth, attractive finish.

- Applying a Decorative Overlay: Decorative overlays or coatings can be used to cover the crazing. These are thin layers of a polymer-based material that can be applied over the existing concrete surface.

how to repair crazing cracks on concrete surfaces

Here's a step-by-step guide on how to repair concrete crazing by resurfacing the concrete using a thin concrete overlay material:

1. Clean the Surface: Begin by cleaning the surface thoroughly. You can use a power washer or a stiff broom along with a concrete cleaning solution to scrub off any dirt, oil, or other contaminants. The overlay material needs a clean surface to properly adhere.

2. Repair Major Cracks or Damage: If there are any larger cracks or damages present apart from the crazing, these should be addressed first using a concrete repair compound. Follow the manufacturer’s instructions to apply it.

3. Mix the Overlay Material: Following the manufacturer's instructions, mix the overlay material. Some products will only require adding water, while others may have more complex mixing procedures. Always follow the manufacturer's instructions for the best results.

4. Apply the Primer: Many overlay materials require the application of a primer before the overlay material is applied. The primer helps the overlay material bond to the existing concrete. Apply the primer as per the manufacturer's instructions.

5. Apply the Overlay Material: Once the primer is dry, you can apply the overlay material. Typically, this is done using a trowel or squeegee. The thickness of the application will depend on the specific product and the depth of the crazing, but generally, it's between 1/8 and 1/4 inch. Make sure to spread the material evenly over the surface.

6. Texture the Surface (Optional): If you desire a textured finish, you can add texture while the overlay material is still wet. This can be achieved using a variety of tools such as a broom, trowel, or texture roller, depending on the desired effect.

7. Allow the Overlay to Cure: After application, allow the overlay to cure according to the manufacturer's instructions. This time can vary, but it is often between 24 to 48 hours. The surface should be kept clear and free from traffic during this time.

8. Seal the Surface: Once the overlay has fully cured, apply a high-quality concrete sealer. This will help protect the new surface from stains, weathering, and wear, and will often enhance the color and appearance of the overlay.

Remember, repairing crazing with a concrete overlay is a cosmetic solution. If crazing is a recurring problem, consider reviewing the concrete mix design, placement methods, finishing techniques, and curing procedures to minimize the occurrence of crazing in future projects.

PRO TIP: You can't fix crazing by sprinkling cement on the surface and working it in. Never sprinkle cement on the concrete to try and fix it.

is concrete crazing normal?

Crazing in concrete is not necessarily abnormal or uncommon, but it's not an ideal or desired characteristic either. These are superficial, very fine cracks that appear on the surface of the concrete, forming a pattern that often resembles a spiderweb or map. They don't affect the structural integrity of the concrete but can detract from its aesthetic appeal.

Crazing usually results from improper curing, overworking the surface during finishing, using a high water-cement ratio in the mix, or rapid drying due to environmental conditions. It's most commonly seen in concrete slabs or flatwork.

So while crazing may not be abnormal in the sense that it does occur under certain conditions, it's something that concrete professionals try to avoid to ensure the best appearance and longevity of the surface. Proper practices in mixing, pouring, finishing, and curing concrete can help prevent crazing.

does concrete crazing get worse over time?

Once formed, crazing cracks usually don't get deeper or wider over time under normal conditions.

However, the visibility of crazing can increase over time due to the accumulation of dirt and debris in the fine cracks. Furthermore, if the concrete surface is exposed to severe wear and tear or aggressive environmental conditions, these superficial cracks can potentially serve as initiation points for more serious deterioration.

For example, in colder climates, if water gets into these cracks and then freezes, it expands and could cause the cracks to enlarge. Similarly, exposure to certain chemicals or salts can also worsen the condition of crazed concrete over time.

So while the crazing itself might not get worse, external factors can lead to a worsening appearance or further surface damage over time. Regular cleaning and maintenance, like sealing, can help mitigate these effects and keep the concrete looking its best.

is crazing considered damage?

Crazing in concrete, while not aesthetically pleasing, is generally not considered structural damage. These are superficial, fine cracks that form a pattern on the surface of the same concrete slab, and they don't typically compromise the integrity or strength of the concrete structure.

what's the difference between cracking and crazing?

While both cracking and crazing are types of fissures that can occur in concrete, there are important differences between the two.

Crazing:

- Crazing refers to a network of fine, shallow cracks on the surface of the concrete. These cracks are typically less than 0.5 mm deep.

- The cracks are usually not interconnected, forming a pattern that often resembles a spider web or the cracked glazing on pottery.

- Crazing is generally an aesthetic issue and doesn't affect the strength of the concrete. Over time, the cracks may become more visible as dirt and grime accumulate in them.

- Crazing is often a result of improper curing, finishing with bleed water visible, or excess water in the concrete mixture, causing the surface cement paste layer of the concrete to shrink more than the underlying layer.

Cracking:

- Cracks in concrete can vary widely in size, from very thin, barely visible surface cracks to larger, more noticeable ones. These can extend deeper into the concrete, unlike crazing.

- Concrete cracks are usually more irregular and can be interconnected.

- Depending on the size and location, cracking can be a serious concern, potentially affecting the structural integrity of the concrete.

- Cracks can form for a variety of reasons, including drying shrinkage, thermal contraction, stress from loads applied to the concrete, and more.

So, the main differences between crazing and cracking lie in their depth, pattern, the potential impact on the whole concrete floor's performance, and their causes. Understanding these differences is crucial in diagnosing issues with a concrete floor installation and determining the appropriate solutions or preventative measures.

are craze cracks and plastic shrinkage cracks the same thing?

No, craze cracks and plastic shrinkage cracks are not the same things. While both are types of cracks that can occur in a concrete slab, they differ in their characteristics and causes.

Crazing:

- Crazing refers to the formation of a network of fine, shallow cracks on the concrete surface. They are typically less than 0.5 mm deep and resemble a spider web or cracked glazing on pottery.

- Crazing usually occurs due to surface shrinkage caused by rapid drying of the surface, high water-cement ratio, or finishing the concrete surface while bleed water is still present.

- Crazing is generally considered a cosmetic issue and does not impact the structural integrity of the concrete.

Plastic Shrinkage Cracks:

- Plastic shrinkage cracks are larger and deeper than crazing cracks. Plastic shrinkage cracking occurs when the surface of the concrete dries out prematurely, and the volume of the concrete shrinks during the plastic concrete(still moldable) stage.

- These cracks can be several feet long and are often parallel to each other, approximately 1 to 3 feet apart. They can penetrate to the mid-depth of a slab.

- Plastic shrinkage cracking can compromise the durability of the fresh concrete and can potentially lead to structural issues if not addressed, particularly if they are wide or deep enough to allow water infiltration.

So, while both craze cracking and plastic (drying) shrinkage cracks are related to shrinkage and drying of the concrete, they differ significantly in their severity, appearance, potential impact on the concrete, and their causes.

In conclusion, crazing in concrete is a common phenomenon that results in a network of fine, shallow cracks on the surface of the material. While primarily a cosmetic issue, it can detract from the aesthetic appeal of the concrete and, under specific conditions, may lead to further surface degradation.

Prevention strategies, including proper curing, avoiding overworking the surface, and appropriate water-cement ratios, can help avoid crazing. If crazing occurs, it can be addressed using methods such as cleaning, sealing, or resurfacing, depending on the severity.

Understanding what crazing is, why it occurs, and how to address it can help maintain the durability and appearance of your concrete structures.