Rebar in Concrete Footings:

The Ultimate Guide for a Solid Foundation

Welcome to my blog post about "Rebar in Concrete Footings". As a concrete contractor specializing in concrete construction, I understand the importance of reinforcing concrete footings with rebar.

In this post, I will be discussing the various types of footings used in concrete construction, including slab, foundation, pier, deck, and column footings.

I'll explain the different types of rebar available, recommended sizes and spacing of rebar, tying vertical wall reinforcement, code requirements, and how to calculate the amount of rebar needed for a specific type of footing.

Rebar is a vital component in concrete construction that enhances the strength and durability of concrete footings, making them more resistant to tensile and compressive forces. By using rebar, you can prevent structural failure and ensure that your building is strong and long-lasting.

why use rebar in concrete footings

Using rebar for concrete footings is important for several reasons:

- Increased strength and durability: Rebar provides tensile strength to the concrete footings, which helps to resist cracking and breakage due to the weight of the structure above and the natural settling of the ground. This additional reinforcement ensures the footings can better support the load and remain stable over time.

- Improved load distribution: Rebar helps to distribute the weight of the structure evenly across the footing, reducing the risk of uneven settlement and potential damage to the structure. This uniform load distribution is particularly important in areas with variable soil conditions or where the footing is subject to heavy or concentrated loads.

- Crack control: Concrete is strong in compression but weak in tension. As a result, it is susceptible to cracking under tensile stresses, such as those caused by ground movement, temperature fluctuations, or shrinkage during curing. Rebar reinforces the concrete, providing tensile strength and helping to control and minimize the size and frequency of cracks in the footing.

- Enhanced structural integrity: Adding rebar in footings connects the footing to the rest of the structure, such as columns, walls, or slabs, creating a cohesive and unified system that works together to support the building. This interconnectedness enhances the overall structural integrity and stability of the building.

- Compliance with building codes and standards: Many building codes and standards require the use of rebar for footings to ensure adequate structural performance and safety. Using rebar in your footings will help ensure your construction project meets these requirements, reducing the risk of costly issues, delays, or penalties.

what is rebar?

Rebar, short for reinforcing bar, is a steel bar or mesh of steel wire used to strengthen and hold the concrete in tension. It's essential in footings because it helps to distribute loads and resist cracking and shifting, ensuring the overall stability and longevity of the structure.

Types of rebar

- Steel rebar: The most common type of rebar used in construction, steel rebar provides excellent strength and durability.

- Fiberglass rebar: A lightweight, corrosion-resistant alternative to steel rebar, fiberglass rebar is ideal for environments with high moisture or chemical exposure.

- Stainless steel rebar: Offering exceptional corrosion resistance, stainless steel rebar is a more expensive option but can be a cost-effective choice in the long run for structures exposed to corrosive elements.

- Galvanized rebar: Steel rebar with a protective zinc coating, galvanized rebar resists corrosion better than uncoated steel.

- Epoxy-coated rebar: Another corrosion-resistant option, epoxy-coated rebar features a protective epoxy coating that prevents rusting.

Rebar sizes and grades

- Size: Rebar comes in various sizes, typically numbered from #3 (3/8") to #18 (2 1/4"). The size of the rebar you choose will depend on the size and load-bearing capacity of the footing.

- Length: The most common lengths for rebar bars are 10' and 20'. But you can purchase them in lengths from 2' long to 60' long at different locations.

- Grade: Rebar grades indicate the yield strength of the steel, with common grades being 40, 60, and 75. The higher the grade, the stronger the rebar.

rebar requirements for footings:

This table serves as a general reference, and the specific rebar size requirements for a particular project should be determined by consulting a structural engineer or following the appropriate building codes and design specifications.

what size rebar to use for footings

| Footing Type | Suggested Rebar Sizes |

|---|---|

| Residential Wall Footings | #4, #5 |

| Column Footings | #5, #6, #8 |

| Deck Footings | #4, #5 |

| Slab Footings | #4, #5 |

| Grade Beams | #5, #6, #8 |

| Retaining Wall Footings | #5, #6, #8 |

| Bridge Pier Footings | #8, #9, #10 |

| Industrial Footings | #6, #8, #10 |

the placement of rebar for concrete slab footings

What size and type to use:

The size and type of rebar used in concrete slab footings will depend on the specific requirements of your project, including the size of the slab, the load it will support, and local building codes.

Common rebar sizes range from #3 to #6 for slab footings, with #4 being the most commonly used.

As for the type of rebar, steel rebar is the most common choice due to its excellent strength and durability. However, other types of rebar, such as fiberglass, stainless steel, galvanized, or epoxy-coated rebar, can be used depending on the specific needs of the project, including corrosion resistance or specific environmental considerations.

How many rebars to use in the footing:

The number of rebars used in a slab footing will depend on the footing's dimensions, the spacing of the rebar, and the required reinforcement.

Most slab footings 24" wide have 2 or 3 bars laid in a flat horizontal position throughout the entire footing length.

The placement of rebars in the footing:

In slab footings, rebars are typically placed in a grid pattern, with both horizontal and vertical bars intersecting at regular intervals. This grid provides a balanced reinforcement throughout the slab, ensuring adequate tensile strength and crack resistance.

Horizontal rebars, also known as main bars, are placed parallel to the length of the slab, while vertical rebars, or distribution bars, run perpendicular to the main bars. The rebars should be supported by chairs, spacers, or bar supports to maintain proper positioning and concrete cover during the concrete pour.

How far apart should rebar be in a slab footer:

Rebar spacing in a slab footer will depend on the size of the slab, the load it will support, and local codes. Generally, rebar spacing in slab footings ranges from 12 to 24 inches, both for horizontal and vertical bars.

How to install rebar in slab footings:

To install rebar in slab footings, follow these steps:

- Begin by laying out the horizontal and vertical rebars according to the specified spacing, creating a grid pattern. Ensure that the rebars overlap at the intersections, with a minimum lap length of 40 times the rebar diameter.

- Use rebar chairs or spacers to support the rebars above the ground or formwork, ensuring proper positioning and maintaining the required concrete cover (typically 2 to 3 inches).

- Secure the intersections of the rebars using rebar ties or tie wire, using appropriate tying techniques such as snap ties, wrap and loop ties, figure-eight ties, or saddle ties.

- Once the rebar grid is properly installed and secured, proceed with pouring the concrete, ensuring that the concrete fully encases the rebars and maintains the required concrete cover.

It is essential to consult with a structural engineer or follow local building codes to determine the appropriate number of rebars and spacing needed for your specific application.

How To Install Rebar Reinforcement in Foundation Footings

The placement of rebar in foundation footings involves several steps to ensure proper reinforcement of the footing and foundation. Here is a general guideline on how to install rebar in foundation footings:

- Determine the size and spacing of rebar required for the foundation footing based on the weight of the structure and the local building codes. The most common size used for residential construction is #4 bars securely tied in a grid 12" - 24" on center.

- Prepare the footing trench by excavating to the required depth and width. Ensure that the trench is level and free from debris.

- Place rebar in the trench in the required orientation and spacing, ensuring that it's not in contact with the soil.

- Tie the rebar together at the intersections using wire ties. The tying method used should provide sufficient support to the rebar.

- Elevate the rebar off the bottom of the footing using bar chairs or cement bricks. This will ensure that the rebar is centered within the footing and does not touch the soil.

- Pour concrete into the footing, ensuring that it completely covers the rebar and fills the entire trench.

- Use a vibrator or other tool to consolidate the concrete around the rebar and remove any air pockets.

- Float the surface of the concrete as required, depending on the type of foundation wall being built.

Rebar Placement for Concrete Deck Footings

The most commonly used rebar size for concrete deck footings and sonotubes is #4 (1/2-inch diameter) or #5 (5/8-inch diameter) rebar. These sizes provide adequate reinforcement and tensile strength for typical deck applications.

In a sonotube, vertical rebars are commonly used to reinforce the concrete. The number of rebars needed depends on the diameter of the sonotube and the load requirements of the deck. A common configuration for deck footings is to use 4 vertical rebars evenly spaced around the interior of the sonotube.

For larger sonotubes or higher load requirements, you might need to increase the number of rebars or consult a structural engineer for guidance.

In addition to vertical rebars, you may also need horizontal stirrups (circular or square-shaped) within the sonotube to provide additional reinforcement, especially in areas prone to seismic activity. The horizontal stirrups are placed at regular intervals along the length of the vertical rebars, with the spacing determined by the specific needs of the project.

Rebar in Pier Footings:

is rebar needed for pier footings?

Incorporating rebar into pier footings is crucial for reinforcing the concrete and ensuring the structure's stability and durability. We typically advise using at least two pieces of #4 rebar (1/2-inch diameter) placed vertically in an 8-inch-diameter concrete pier that supports a structure.

This reinforcement provides additional tensile strength to the pier, reducing the risk of cracking and improving its load-bearing capacity.

For larger-diameter piers, it's essential to increase the amount of vertical rebar to maintain the necessary reinforcement. In these cases, it's advisable to use four or more pieces of vertical rebar, depending on the pier's diameter and the load requirements of the structure.

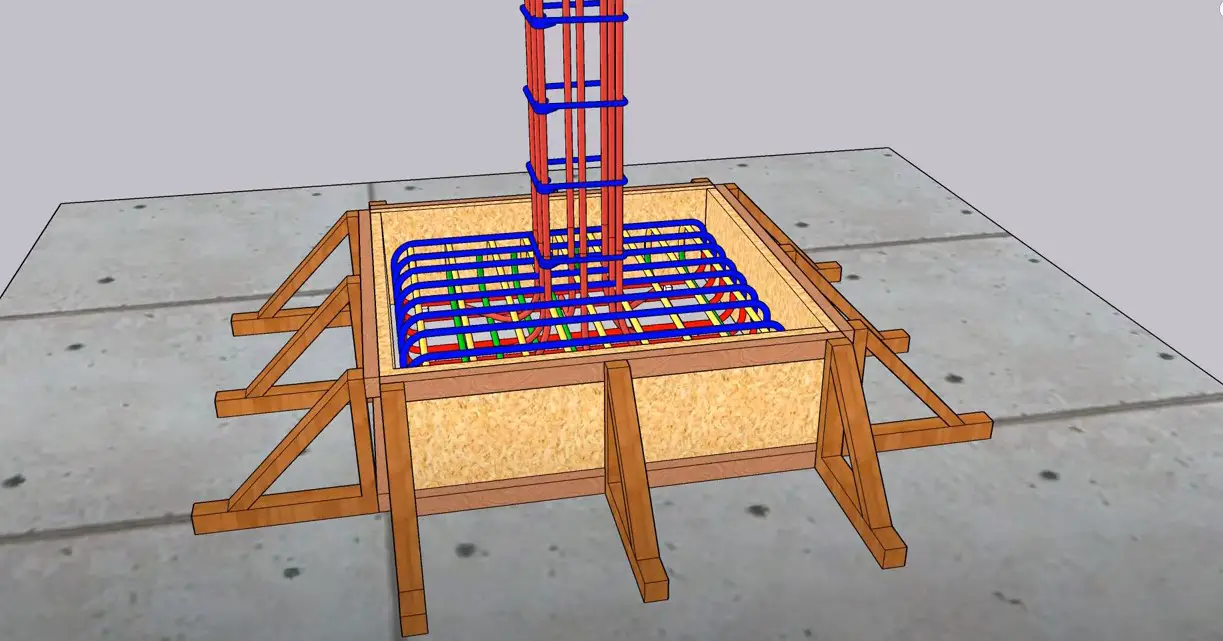

Rebar reinforcement in column footings

Rebar is essential for reinforcing concrete columns, as it helps resist tensile forces that can cause buckling or bursting. To create a rebar "cage" for a column cut four vertical No. 4 rebar pieces to span from the top of the column to the bottom of the footing.

Bend the last six inches of each bar at a 90-degree angle to form an L shape, allowing three inches of clearance above and below the rebar.

Next, cut No. 3 rebar to create rectangular stirrups that will encircle the vertical bars, spaced one foot apart vertically. Bend the stirrups and secure the overlaps with securing ties (wire).

Insert the vertical bars into the stirrups, tying the top and bottom ones first to establish the cage's shape. Ensure the L-shaped bottom points away from the column center.

Slide the remaining stirrups into position and tie each corner to an upright bar. Place the completed cage in the footing using dobies (small concrete blocks) to maintain spacing, with three inches of clearance from the footing bottom and the column top.

Pour the footing with the rebar cage in place, and when it dries, build the column forms around the rebar.

Code Requirements for Rebar in Footings

The code requirements for rebar being used in concrete footings vary depending on the jurisdiction and the specific building codes in your area.

However, there are some general guidelines provided by the American Concrete Institute (ACI) that serve as a basis for many local building codes:

minimum rebar size in footings:

- Typically, #4 rebar (1/2-inch diameter) is the minimum size used for concrete footings. The actual size needed depends on the footing's load requirements, dimensions, and soil conditions.

rebar spacing in footings:

- The spacing of rebars in footings depends on the specific design and load requirements. As a general rule, rebars should be placed no more than 18 inches apart, as specified by the ACI code. In some cases, closer spacing may be necessary for additional reinforcement.

minimum rebar coverage for footings

- The rebar should be embedded within the fresh concrete at the proper depth to protect it from corrosion and ensure proper bonding with the concrete.

- The ACI recommends a minimum cover of 2 inches for footings in contact with soil and 1.5 inches for footings exposed to weather or soil, but not in direct contact.

how far should rebar be overlapped & splices

- When rebars need to be joined or overlapped, the ACI code specifies minimum lap lengths for proper bonding. For #4 rebar, the minimum lap length is 40 times the rebar diameter (20 inches for #4 rebar). Rebar splices should be staggered and spaced according to the specific requirements of the project.

VERTICAL REBAR REINFORCEMENT:

- In some cases, vertical reinforcement may be required, particularly for tall or slender walls, columns, or footings subject to bending. The specific reinforcing bar sizes for vertical rebar will depend on the building design and load conditions.

How To Calculate Rebar Needed for a Concrete Footing

Calculating the amount of rebar needed for a concrete footing requires knowledge of the footing's dimensions, the required rebar size, and the spacing between the rebars. Here's an example of a foundation footing to estimate the rebar needed for this type of footing:

Calculate the Perimeter of Your Concrete Foundation. Suppose you have a foundation that is 120 feet long and 50 feet wide. To calculate the linear footage of your footing, remember that a linear foot is a one-dimensional measurement, not to be confused with a square foot. You need to add all sides lengths of your footing instead of multiplying the length by the width.

Here's the formula: 50 + 50 + 120 + 120 = 340 linear feet. Now, let's determine how much rebar you need for this length.

Typically, footing rebar requirements include one rebar for every 8 inches of footing width. If your footings are 16 inches wide, you'll need two rods across the width of your footings.

To calculate the total rebar needed, multiply the linear footage of your foundation (340) by the number of rebar sticks required across the width of your footings (2). This gives you 680 lineal feet of rebar.

Rebar is typically available in lengths of 10, and 20, feet. To determine how many rods you need based on these available rebar lengths, you can divide 640 by 10 (64 bars) or 640 ÷ 20 for 32 bars, the amount you choose will depend on your desired length.

For more help calculating how much rebar in footings you need, try this rebar calculator.

How To Tie Rebar using Wire Ties

Tying the rebar together is an essential process to ensure the proper positioning and spacing of the rebar within the concrete. This helps to maintain the structural integrity and strength of the footing.

There are several methods used today to tie steel rebar in footings, including manual tying, loop wrap and saddle tie, and using rebar tying tools. Here's an overview of these methods:

Manual Tying: Manual tying is the traditional method of tying rebar, which involves using a tie wire to bind the intersecting rebars together. Here are the steps for manual tying:

- Cut a piece of tie wire approximately 6 inches long.

- Hold the two intersecting rebars together at the desired position and spacing.

- Wrap the tie wire around the intersection, ensuring that it is tight and secure.

- Twist the ends of the tie wire together using pliers until the connection is tight and the rebars are held firmly in place.

- Trim any excess wire and repeat this process at every intersection of the rebar grid.

Double Loop Ties: Rebar loop ties are pre-formed wire ties (with loops on each end) designed for a quicker and more efficient method of tying rebar. They come in various lengths and can be used with a yo-yo tie tool. To use a loop snap tie:

- Position the intersecting rebars as required.

- Wrap the loop tie around the intersection and line up the loops on each end.

- Insert the hook on the yo-yo tool into both loops and pull snug.

- Twist the yo-yo in a clockwise motion until the wire is twisted tightly to the rebar.

Battery-Powered Rebar Tying Tool: Rebar tying tools, such as battery-powered rebar tier machines, are designed to make the process of tying rebar faster and more efficient. These tools automatically wrap and twist the tie wire around the intersecting rebars, significantly reducing the time and effort required. Here's how to use a rebar-tying tool:

- Position the intersecting rebars as required.

- Place the rebar tying tool over the intersection, ensuring that the wire guide is correctly aligned with the rebars.

- Squeeze the trigger or operate the tool according to the manufacturer's instructions.

- The tool will automatically wrap and twist the tie wire around the rebars, creating a secure connection.

How To Set Vertical wall reinforcement in Footings

Setting vertical rebar in footings is crucial for providing structural stability and reinforcement to your concrete basement walls. Here are some basic guidelines to follow when setting vertical rebar in footings:

- Rebar size and grade: Use the appropriate size and grade of rebar as specified by the structural engineer or building code. Common sizes used for footings are #4, #5, and #6 rebar.

- Rebar spacing: Typically, vertical rebar is spaced at a minimum distance of 3 times the rebar diameter or between 12 - 24 inches apart. However, the specific spacing requirements depend on the footing design, load, and other factors.

- Concrete cover: Ensure that there is adequate concrete cover around the rebar to protect it from corrosion and maintain the footing's durability. The minimum concrete cover for footings is generally 3 inches, but it may vary depending on the specific building code and exposure conditions.

- Rebar bending: Bend the bottom end of the vertical rebar at a 90-degree angle, creating an L-shape. This helps to integrate the vertical rebar with the footing and improve the overall structural stability. The bent portion should extend horizontally into the footing, maintaining the specified concrete cover.

- Rebar placement: Set the vertical rebar in the footing so that it is plumb (vertically straight). Use rebar chairs, dobies, or other supports to hold the rebar in place and maintain the proper position during concrete placement.

- Tying vertical wall reinforcement: Tie the vertical rebar to horizontal rebar or stirrups using tie wire to create a rigid reinforcement grid. This helps to maintain the proper position and spacing of the rebar during concrete placement and ensures an even distribution of reinforcement throughout the footing.

- Cast in place concrete: Pour the concrete around the rebar grid, ensuring that the concrete flows and fills all voids between the rebars. Use a vibrator to consolidate the concrete and eliminate any air pockets or voids that could compromise the footing's strength and durability.

DOES BENDING REBAR WEAKEN IT?

Bending rebar can potentially weaken it if not done correctly. When rebar is bent beyond its specified bend radius or subjected to excessive force, it can lead to stress fractures or cracks, which may compromise its structural integrity.

However, if the bending process is performed according to the recommended guidelines and with the appropriate tools, it will maintain its strength and continue to provide the necessary reinforcement for concrete structures.

WHAT DO YOU USE TO BEND REBAR?

Here are some tools commonly used to bend rebar:

- Manual rebar bender

- Rebar cutter bender (combination tool)

- Rebar bending machine (electric or hydraulic)

- Hickey bar (or rebar hickey)

- Portable rebar bender

- Table-mounted rebar bender

WHAT DO YOU USE TO CUT REBAR?

Here are different methods commonly used to cut rebar:

- Manual bolt cutters

- Rebar cutter bender

- Angle grinder with a cutting wheel

- Electric portable rebar cutter

- Chop saw with a metal cutting blade

- Gas powered cut-off saw with metal cutting blade

- Plasma cutter

Can You Put Too Much Rebar In a Footing?

Yes, it is possible to put too much rebar in a concrete footing, which can lead to issues with the overall performance and structural integrity of the footing.

What are beam corner bars used for? Beam corner bars are rebar that is placed in the corners of the beam to provide additional support and strength to the structure. The size and spacing of beam corner bars depend on the weight and size of the structure being supported. Proper placement of beam corner bars ensures that the load is evenly distributed, preventing cracking and structural failure.

Is rebar used in precast concrete? Rebar is placed in precast concrete footings to reinforce them and provide additional support.

IN CONCLUSION:

It's essential to consult with a structural engineer or refer to your local building codes for the specific requirements related to rebar in concrete footings in your area.

Some other interesting topics: