is stamped concrete slippery?

Hey there! If you've been considering stamped concrete for your home, you might be wondering if it's slippery.

Contrary to popular belief, stamped concrete itself is not inherently slippery – the issue typically lies with the sealer.

Concrete is a porous material, so it's crucial to seal it after curing to prevent liquid absorption, spills, and stains. Outdoor concrete surfaces are often sealed with clear acrylic, which not only intensifies the sealed concrete's color but also repels water.

The sealer dries transparently, forming a plastic-like film over the concrete. Since the sealer is water-resistant, water tends to accumulate on the surface, leading to slippery conditions.

This problem is particularly prevalent when the sealer is applied in a thick coating. The good news is that there are multiple ways to improve slip resistance and make a stamped surface or concrete slab less prone to slips.

What makes stamped concrete slippery?

A stamped concrete patio can become slippery due to several factors, which I've listed below:

- Sealer type: High-gloss acrylic sealers can create a slick surface, especially when wet. Use penetrating sealers or sealers with a lower sheen, like D1 Stamped Concrete Sealer. Apply the sealer in very thin coats versus one thick coat.

- Surface texture: Using smooth-textured stamps during the stamping process can lead to a slippery surface. Opt for stamps with an appropriate amount of heavy texture to improve traction.

- Slope: If the stamped concrete doesn't have the proper slope, water can pool, making it more slippery. Proper drainage is key.

- Mold and mildew: These can grow on damp, sealed, and unsealed surfaces, increasing slipperiness. Regular cleaning is essential to prevent buildup.

- Improper installation: Poorly installed stamped concrete may have an uneven surface, contributing to slipperiness.

- Footwear: The type of footwear you wear can also affect the slipperiness of stamped concrete. Shoes with smooth soles or high heels can be more prone to slipping on wet, surfaces, including stamped concrete.

is stamped concrete slippery around a pool?

Yes, stamped concrete can be slippery around swimming pools, especially if the pool deck is wet.

The combination of the wrong sealer, water, and a smooth stamped surface can make it difficult to maintain traction, specifically with wet bare feet, which can be dangerous for swimmers.

To help minimize the risk of slips and falls, it's important to choose a stamped concrete pattern that has enough texture for safe walking and to apply a slip-resistant sealer

First, choose a stamp pattern that has a full texture like natural stone, Ashlar Slate, Fieldstone, or even 16" Barnboards.

Second, choose a sealer designed for pool decks, like D1 from DecoCrete supply or LastiSeal from RadonSEAL.

is stamped concrete slippery when wet, and why?

Yes, stamped concrete can become slippery when wet, especially with high-gloss sealers. A high-gloss sealer creates a thin topical coating on the surface of the concrete that can create a slippery surface when it gets wet.

This type of topical sealer makes water bead up on the surface of the concrete, which can reduce the friction between the surface and the bottom of your shoes or wet feet, making it easier to slip and fall.

To prevent slips and falls, it's important to choose a slip-resistant penetrating sealer or a sealer with slip resistant additives that will help to maintain traction on wet concrete surfaces.

Is Stamped Concrete Slippery in the Winter, and Why?

Yes, a stamped concrete patio can be slippery in the winter, especially if it's cold and frosty outside.

When the surface of the concrete is cold, it can cause frost or ice to form on the surface, which can make it more slippery.

To prevent slips and falls in the winter, it's important to keep the surface clear of snow and ice and to use sand or kitty litter to improve traction.

Also, to help combat slipping, use a sealer designed for cold weather, like EnduraSeal Winter Guard, and avoid using de-icing chemicals that can damage the regular concrete.

the best non-slip additives for stamped concrete sealer

To make acrylic sealers on your stamped concrete less slippery, consider adding a non-slip additive to your sealer. Some popular options include:

- H&C SharkGrip: A micronized polymer that increases traction without affecting the sealer's appearance.

- Gator Grip Slip Resistant Additive: A fine-textured additive that can be mixed with sealers and sprayed or rolled on concrete to add slip resistance.

- Course Grit Non-Slip Additive: A powder that's mixed with the sealer to create a gritty texture and an anti-slip surface.

- Armor Fine by Foundation Armor: A polyethylene additive that enhances traction without changing the sealer's color or texture.

All these additives when mixed correctly with sealer and applied properly, work great for adding some slip-resistance and traction to new or existing stamped concrete.

how to fix slippery stamped concrete

If you already have slippery stamped concrete, don't worry – there are ways to fix it. Here are some steps you can take:

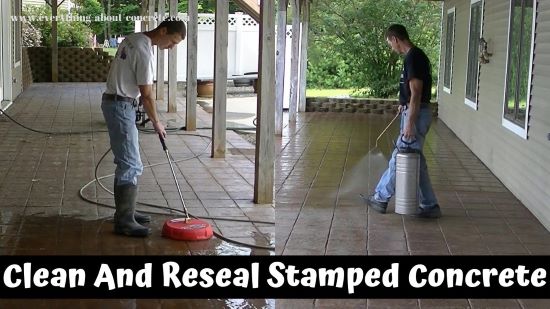

- Clean the surface: The first step is to clean the surface of the concrete to remove any dirt, mold, and mildew that could be making it slippery. Use a pressure washer or a garden hose and a stiff-bristled brush to scrub the surface clean.

- Apply a non-slip additive: Mix a non-slip additive, like the one's suggested above, with a new coat of sealer and apply it to the surface.

- Apply a textured slip-resistant coating: Mapecoat Deck T is a water-based, slip-resistant coating specially designed for use on new and previously coated broomed and stamped concrete. Non-slip coatings are available in a variety of colors and textures and can be applied over the sealer to create a non-slip surface.

- Sandblasting or soda blasting: This process involves lightly blasting the surface with fine sand or baking soda to remove the existing sealer and create a less slippery texture. Then re-apply a non-slip or penetrating sealer to give you better slip resistance. It's best to hire a professional for this method, as it requires specialized equipment and expertise.

how to make "new" stamped concrete less slippery

To ensure your stamped concrete patio isn't slippery from the get-go, follow these tips:

- Choose a textured stamp pattern: Opt for a stamp with more texture to provide better traction underfoot.

- Avoid using a fresno or hand trowel: Avoid smoothing the concrete with a fresno or hand trowel before stamping. Smooth the concrete with a hand float instead as this leaves your patio surface with more texture after stamping it.

- Use a low-sheen sealer: Avoid high-gloss sealers, and instead choose one with a lower sheen or a penetrating sealer, like the D1 from DecoCrete or LastiSeal from Radonseal.

- Add a non-slip additive: Mix a slip-resistant additive, such as H&C SharkGrip or Gator Grip Non-Slip, with your sealer to increase traction.

- Ensure proper drainage: Make sure water can easily flow away from the surface to avoid pooling.

- Keep it clean: Regularly clean your stamped concrete to prevent the buildup of dirt, mold, and mildew, which can make the surface slippery.

other ways to improve traction on stamped concrete surfaces

There are several other materials you can use as non-slip additives to improve the traction of your stamped concrete surface, including:

- Silica Sand: Silica sand is a type of sand that is often used as a non-slip additive for decorative concrete. It's inexpensive, readily available, and can be mixed into the sealer before it is applied to the concrete surface. Silica sand creates a rough texture that provides traction on a smooth surface, even when the surface is wet.

- Polypropylene Beads: Polypropylene beads are tiny plastic beads that can be mixed into the sealer to create a non-slip surface. They are lightweight and float to the top of the sealer when it is applied, creating a textured surface that provides traction.

- Polymer Beads: Polymer Beads are clear, lightweight, chemical-resistant polycarbonate beads. These durable Polymer Beads can be mixed with a concrete sealer and used as an anti-skid additive or texturizing agent.

- Aluminum Oxide: Aluminum oxide is a fine powder that can be mixed into the sealer to create a non-slip surface. It creates a rough texture that provides traction, even when the surface is wet. Aluminum oxide is more expensive than silica sand or polypropylene beads, but it is also more durable.

- Rubber Granules: Rubber granules are small pieces of rubber that can be mixed into the sealer to create a non-slip surface. They are soft and flexible, which can provide additional cushioning and reduce the risk of injury if someone falls on the surface. Rubber granules are more expensive than silica sand or polypropylene beads, but they can also provide a more comfortable surface for walking and standing.

- Glass Beads: Glass beads are small, transparent beads that can be mixed into the sealer to create a non-slip surface. They reflect light and create a sparkling effect on the surface, which can be visually appealing. Glass beads also help reduce slipping hazards, especially in wet conditions.

6 Reasons to hire a Concrete Contractor to fix your slippery stamped concrete pool deck

Hiring an experienced concrete contractor to fix slippery stamped concrete is often a better choice for several reasons:

- Expertise: Professional concrete contractors possess the necessary knowledge and skills to assess the problem and identify the best solution. They are well-versed in various techniques and products used to enhance the slip resistance of stamped concrete.

- Proper application: Making decorative concrete less slippery involves techniques like applying non-slip additives or texture coatings, or sandblasting. An experienced contractor will ensure these methods are executed correctly, avoiding potential damage to your concrete surface.

- Safety: Handling chemicals, such as solvents, or using specialized equipment for sandblasting can be dangerous. A professional contractor will follow proper safety protocols, reducing the risk of accidents or damage to the surrounding area.

- Time and effort: Fixing slick stamped concrete can be time-consuming and labor-intensive. Hiring a professional allows you to save time and effort, ensuring the job is done efficiently and correctly.

- Warranty and liability: Many experienced concrete contractors offer warranties on their work, providing you with peace of mind. If any issues arise after the project is completed, the contractor is liable for addressing and resolving them.

- Long-term results: A professional contractor will use high-quality materials and proven techniques that provide long-lasting results, preventing the need for frequent repairs or maintenance.

in conclusion:

Stamped concrete is a versatile and attractive flooring, patio, or pool deck option that can mimic the appearance of natural stone, tile, wood, or brick.

While it may become slippery under certain conditions, this issue can be effectively managed with the right techniques and materials. When choosing stamped concrete, keep these essential points in mind:

- Opt for a textured stamp pattern and a low-sheen sealer to improve traction.

- Use non-slip additives in the sealer to enhance slip resistance.

- Ensure proper drainage and regular cleaning to prevent slippery conditions.

- In colder climates, use sealers designed for winter conditions and avoid de-icing chemicals that can damage the concrete.

If you encounter a slippery stamped concrete issue, consider hiring an experienced concrete contractor to resolve it safely and effectively. By taking these precautions, you can enjoy the beauty and durability of stamped concrete without compromising safety.

frequently asked questions

Here are some frequently asked questions and answers about stamped concrete that cover different aspects than those discussed previously:

1. How long does stamped concrete last?

- Answer: With proper installation, maintenance, and sealing, stamped concrete can last for decades. Regular cleaning and resealing every 2-3 years (or as needed) will help prolong its lifespan and keep it looking its best.

2. How much does stamped concrete cost?

- Answer: The cost of stamped concrete can vary depending on factors such as the complexity of the design, the size of the project, labor rates, and the quality of materials used. On average, stamped concrete costs between $15 and $25 per square foot, but prices may differ based on your location and specific project requirements.

3. Can stamped concrete be repaired?

- Answer: Yes, stamped concrete can be repaired if it becomes damaged or cracked. Small cracks can be filled with a matching colored caulk, while more extensive damage may require a professional to apply a polymer-modified cement overlay or other repair techniques.

4. How do I maintain my stamped concrete?

- Answer: Regular cleaning and resealing are crucial for maintaining stamped concrete. Sweep or blow off debris, wash the surface with mild detergent and water, and rinse thoroughly. Reseal the concrete every 2-3 years, or as needed, to protect the surface and maintain its appearance.

5. Can stamped concrete be installed over existing concrete?

- Answer: Yes, stamped concrete can be installed over an existing concrete surface using a thin overlay, provided that the existing concrete is in good condition and properly prepared. The overlay is typically a polymer-modified cement that can be stamped with the desired pattern.

6. Can I use stamped concrete indoors?

- Answer: Absolutely! Stamped concrete is a versatile flooring option that can be used both indoors and outdoors. It's an excellent choice for basements, kitchens, and living areas, adding a unique and attractive design element to your interior spaces.

Related Topics on stamped concrete: